Nissan Juke Service and Repair Manual : Unlock sensor

Component Function Check

1.CHECK FUNCTION

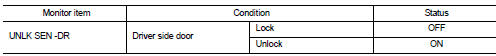

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “UNLK SEN -DR” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Unlock sensor is OK.

NO >> Refer to DLK-270, "Diagnosis Procedure".

Diagnosis Procedure

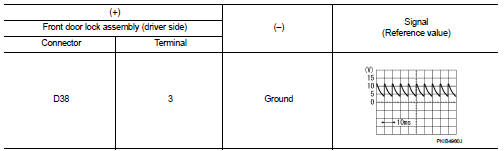

1.CHECK BCM OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check signal between front door lock assembly (driver side) harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

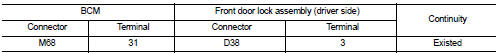

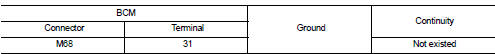

2.CHECK UNLOCK SENSOR CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and front door lock assembly (driver side) harness connecto

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

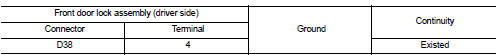

3.CHECK UNLOCK SENSOR GROUND CIRCUIT

Check continuity between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK UNLOCK SENSOR

Refer to DLK-271, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace front door lock assembly (driver side).

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

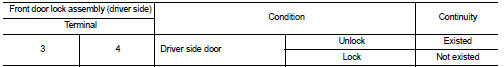

1.CHECK UNLOCK SENSOR

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check continuity between front door lock assembly (driver side) terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace front lock assembly (driver side).

Shift P warning lamp

Shift P warning lamp

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “LCD” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to t ...

Other materials:

How to set SRT code

Description

OUTLINE

In order to set all SRTs, the self-diagnoses as in the “SRT ITEM” table must

have been performed at least

once. Each diagnosis may require actual driving for a long period of time under

various conditions.

SRT ITEM

The table below shows required self-diagnostic items t ...

Wheel alignment

Inspection

DESCRIPTION

CAUTION:

• The adjustment mechanisms of camber, caster, and kingpin inclination angles

are not included.

• If camber, caster, or kingpin inclination angle is outside the standard, check

front suspension parts

for wear and damage. Replace suspect parts if a malfunction ...

Draining

WARNING:

• Never remove radiator cap when engine is hot. Serious burns may occur from

high-pressure engine

coolant escaping from radiator.

• Wrap a thick cloth around the radiator cap. Slowly turn it a quarter of a turn

to release built-up pressure.

Then turn it all the way.

1. Connect dr ...