Nissan Juke Service and Repair Manual : P1805 brake switch

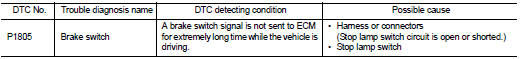

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Fully depress the brake pedal for at least 5 seconds.

3. Erase DTC.

4. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to EC-734, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch OFF.

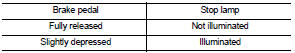

2. Check the stop lamp when depressing and releasing the brake pedal.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

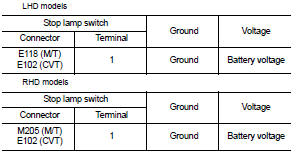

2.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check the voltage between stop lamp switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E105, M77, M84, M201 (RHD models with M/T)

• 10 A fuse (No. 38)

• Harness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

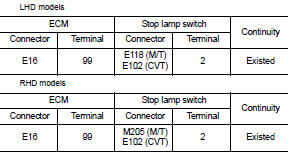

4.CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect stop lamp switch harness connector.

2. Disconnect ECM harness connector.

3. Check the continuity between ECM harness connector and stop lamp switch harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK STOP LAMP SWITCH

Refer to EC-735, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace brake pedal assembly.

6.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK STOP LAMP SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

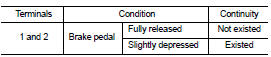

3. Check the continuity between stop lamp switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK STOP LAMP SWITCH-II

1. Adjust stop lamp switch installation. Refer to BR-22, "Inspection and Adjustment" (LHD models), BR-90, "Inspection and Adjustment" (RHD models).

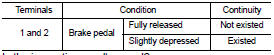

2. Check the continuity between stop lamp switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace brake pedal assembly. Refer to BR-89, "Removal and Installation".

P1715 input speed sensor

P1715 input speed sensor

Description

ECM receives input speed sensor signal from TCM via the CAN communication

line. ECM uses this signal for

engine control.

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P1715 is displ ...

P2100, P2103 throttle control motor relay

P2100, P2103 throttle control motor relay

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 se ...

Other materials:

Control valve

Exploded View

COMPONENT PARTS LOCATION

1. Transaxle assembly

2. Control valve

3. Bracket

4. O-ring

5. Oil strainer assembly

6. Magnet

7. Drain plug gasket

8. Drain plug

9. Oil pan mounting bolt

10. Oil pan

11. Oil pan gasket

12. Lock nut

13. Washer

14. Manual plate

15. Co ...

Brake master cyl

Exploded View

2WD

1. Reservoir cap

2. Oil strainer

3. Reservoir tank

4. Cylinder body

5. Pin

6. O-ring

7. Grommet

: Apply polyglycol ether based

lubricant.

: Apply brake fluid.

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

4WD

1. Reservoir cap

2. Oil strai ...

B2604 shift position

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2604 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2604 is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...