Nissan Juke Service and Repair Manual : P2100, P2103 throttle control motor relay

DTC Logic

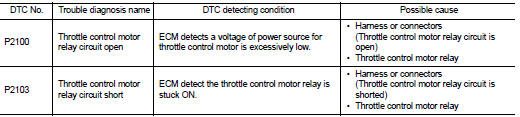

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 8 V.

Witch DTC is detected? P2100 >> GO TO 2.

P2103 >> GO TO 3.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P2100

1. Turn ignition switch ON and wait at least 2 seconds.

2. Start engine and let it idle for 5 seconds.

3. Check DTC.

Is DTC detected? YES >> Go to EC-737, "Diagnosis Procedure".

NO >> INSPECTION END

3.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P2103

1. Turn ignition switch ON and wait at least 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to EC-737, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

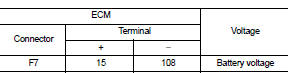

1.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Check voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 2.

2.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-I

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E15.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F1 • IPDM E/R connector E15 • Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK FUSE

1. Disconnect 15 A fuse (No. 64) from IPDM E/R.

2. Check 15 A fuse for blown.

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace 15 A fuse.

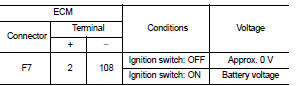

5.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-I

1. Check voltage between ECM harness connector and ground under the following conditions.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 6.

6.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Disconnect IPDM E/R harness connector E15.

4. Check the continuity between ECM harness connector and IPDM E/R harness connector.

5. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F1 • IPDM E/R connector E15 • Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness or connectors.

P1805 brake switch

P1805 brake switch

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Fully depress the brake pedal for at least 5 seconds.

3. Erase DTC. ...

P2101 electric throttle control function

P2101 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P2101 is displayed with DTC P2100, first perform the trouble diagnosis

for DTC P2100. Refer

to EC-737, "DTC Logic".

• If DTC P2101 is disp ...

Other materials:

Engine protection control at low engine oil pressure

Engine protection control at low engine oil pressure : System Diagram

Engine protection control at low engine oil pressure : System Description

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

• The engine protection control at low engine oil pressure warns the driver

of a decrease in engine ...

Engine control system symptoms

Symptom Table

SYSTEM — BASIC ENGINE CONTROL SYSTEM

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & OTHER

1 - 6: The numbers refer to the order of inspection ...

P0045, P0047, P0048 TC boost control

solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...