Nissan Juke Service and Repair Manual : P0045, P0047, P0048 TC boost control solenoid valve

DTC Logic

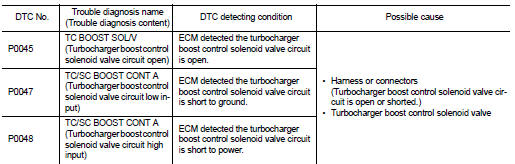

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-174, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

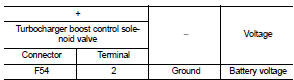

1.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect turbocharger boost control solenoid valve harness connector.

3. Turn ignition switch ON.

4. Check the voltage between turbocharger boost control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

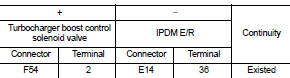

2.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY CIRC

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between turbocharger boost control solenoid valve harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

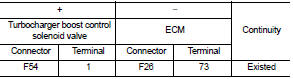

3.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between turbocharger boost control solenoid valve harness connector and ECM harness connector.

4. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE

Check the turbocharger boost control solenoid valve. Refer to EC-175, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace turbocharger boost control solenoid valve. Refer to EM-36, "Exploded View".

Component Inspection

1.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE

1. Turn ignition switch OFF 2. Disconnect turbocharger boost control solenoid valve harness connector.

3. Disconnect hoses connected to turbocharger boost control solenoid valve.

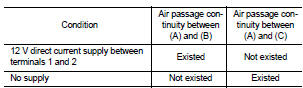

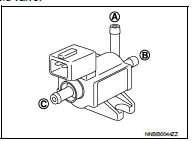

4. Check air passage continuity of turbocharger boost control solenoid valve as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END NO >> Replace turbocharger boost control solenoid valve. Refer to EM-36, "Exploded View".

P0037, P0038 HO2S2 heater

P0037, P0038 HO2S2 heater

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure before conducting ...

P0075 IVT control solenoid valve

P0075 IVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

Combination switch

Exploded View

1. Combination switch

2. Combination switch connector

Removal and Installation

REMOVAL

1. Remove steering column cover. Refer to IP-13, "Removal and

Installation".

2. Remove screws.

3. Disconnect the connector.

4. Pull up the combination switch to remove it.

I ...

Engine emits blue smoke

Description

CHART 19: ENGINE EMITS BLUE SMOKE

Diagnosis Procedure

1.CHECK ENGINE OIL

Check the grade of engine oil. Refer to LU-33, "Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace engine oil. Refer to LU-34, "Refilling".

2.CH ...

Door mirror system (with intelligent key)

LHD

LHD : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

RHD

RHD : Wiring Diagram

For connector termina ...