Nissan Juke Service and Repair Manual : P1805 brake switch

DTC Logic

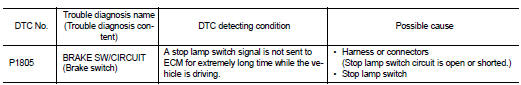

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Fully depress the brake pedal for at least 5 seconds.

3. Erase the DTC.

4. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-374, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check the voltage between stop lamp switch harness connector and ground.

*1: CVT models

*2: LHD with M/T models

*3: RHD with M/T models

Is the inspection result normal? YES >> GO TO 2.

NO >> Perform the trouble diagnosis for power supply circuit.

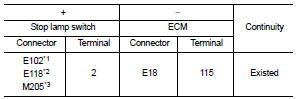

2.CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check the continuity between stop lamp switch harness connector and ECM harness connec

*1: CVT models

*2: LHD with M/T models

*3: RHD with M/T models

3. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK STOP LAMP SWITCH

Check the stop lamp switch. Refer to EC-375, "Component Inspection (Stop Lamp Switch)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace stop lamp switch. Refer to BR-20, "Exploded View" (LHD) or BR-88, "Exploded View" (RHD).

Component Inspection (Stop Lamp Switch)

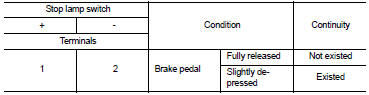

1.CHECK STOP LAMP SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check the continuity between stop lamp switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

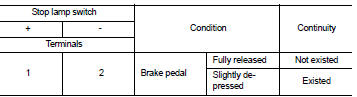

2.CHECK STOP LAMP SWITCH-II

1. Adjust stop lamp switch installation. Refer to BR-9, "Inspection and Adjustment" (LHD) or BR-77, "Inspection and Adjustment" (RHD).

2. Check the continuity between stop lamp switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace stop lamp switch. Refer to BR-20, "Exploded View" (LHD) or BR-88, "Exploded View" (RHD).

P1652 starter motor system COMM

P1652 starter motor system COMM

Description

ECM controls ON/OFF state of the starter relay, according to the engine and

vehicle condition. Models with no

Intelligent Key System transmit a control signal directly to IPDM E/R. On ...

P2100, P2103 throttle control motor relay

P2100, P2103 throttle control motor relay

DTC Logic

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. ...

Other materials:

P1585 G sensor

Description

• G sensor is installed to floor under instrument lower cover.

• G sensor detects longitudinal G and inclination that affects the vehicle and

outputs to ECM using analog voltage.

ECM converts the analog voltage value to digital signal and transmits the signal

to TCM via CAN comm ...

Door lock actuator

Driver side : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Door lock ...

Power door lock system

System Diagram

System Description

DOOR LOCK FUNCTION

• The door lock and unlock switch (driver side) is build into power window

main switch.

• Interlocked with the locking operation of door lock and unlock switch, door

lock actuators of all doors are

locked.

• Interlocked with the unlock ...