Nissan Juke Service and Repair Manual : PTC branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the PTC heater control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of PTC heater control unit.

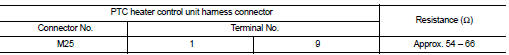

2. Check the resistance between the PTC heater control unit harness connector terminals.

Is the measurement value within the specification? YES >> GO TO 3.

NO >> Repair the PTC heater control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the PTC heater control unit. Refer to HAC-280, "PTC HEATER CONTROL UNIT : Diagnosis Procedure".

Is the inspection result normal? YES (Present error)>>Replace the PTC heater control unit. Refer to HAC.

YES (Past error)>>Error was detected in the PTC heater control unit branch line.

NO >> Repair the power supply and the ground circuit.

MDU branch line circuit

MDU branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the multi display unit f ...

BCM branch line circuit

BCM branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the BCM for damage, bend ...

Other materials:

P0201, P0202, P0203, P0204 fuel injector

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0201, P0202, P0203 or P0204 is displayed with DTC P0263, P0266, P0269 or

P0272 first perform

trouble diagnosis for DTC P0263, P0266, P0269 or P0272. Refer to EC-931, "DTC

Logic".

Diagnosis Procedure

1.CHECK FUEL INJECTOR POWER SUPPLY ...

Brake pedal vibration or operation sound occurs

Description

• Brake pedal vibrates and motor sound from ABS actuator and electric unit

(control unit) occurs, when the

engine starts.

• Brake pedal vibrates during braking.

CAUTION:

Vibration may be felt during brake pedal is lightly depressed (just placing a

foot on it) in the following

...

Control linkage

Exploded View

1. Bracket

2. Selector cable

3. Shifter lever A

4. Selector lever

5. Cable mounting bracket

6. Tapping bolt

7. Shifter cable

8. Grommet

9. M/T shift selector assembly

10. Shifter lever

11. Shifter lever knob

: Always replace after every

disassembly.

: N·m (kg-m, ...