Nissan Juke Service and Repair Manual : P0868 transmission fluid pressure

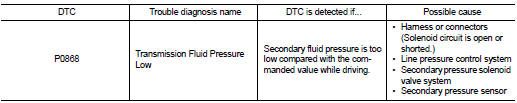

Description

The secondary pressure solenoid valve regulates the secondary pressure to suit the driving condition in response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” in “TRANSMISSION”.

3. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN : 1.0 – 2.0 V If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the voltage (cool down the fluid)

4. Start engine and maintain the following conditions for at least 10 consecutive seconds.

VEHICLE SPEED (accelerate slowly) : 0 → 50 km/h (31 MPH) ACC PEDAL OPEN : 0.5/8 – 1.0/8 RANGE : “D” position

Is “P0868” detected? YES >> Go to TM-234, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

1.CHECK LINE PRESSURE

Perform line pressure test. Refer to TM-188, "Inspection and Judgment".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace damaged parts. Refer to TM-188, "Inspection and Judgment".

2.CHECK SECONDARY PRESSURE SOLENOID VALVE

Check secondary pressure solenoid valve. Refer to TM-225, "DTC Logic".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK LINE PRESSURE SOLENOID VALVE

Check line pressure solenoid valve. Refer to TM-219, "DTC Logic".

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK SECONDARY PRESSURE SENSOR SYSTEM

Check secondary pressure sensor system. Refer to TM-230, "DTC Logic".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK TCM

Check input/output signal. Refer to TM-164, "Reference Value" Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

P0841 transmission fluid pressure SEN/SW A

P0841 transmission fluid pressure SEN/SW A

Description

Using the engine load (throttle position), the primary pulley revolution

speed, and the secondary pulley revolution

speed as input signal, TCM changes the operating pressure of the pri ...

P1585 G sensor

P1585 G sensor

Description

• G sensor is installed to floor under instrument lower cover.

• G sensor detects longitudinal G and inclination that affects the vehicle and

outputs to ECM using analog voltage.

EC ...

Other materials:

B1145 curtain air bag module RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

Can communication

CAN COMMUNICATION : System Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped ...