Nissan Juke Service and Repair Manual : P0841 transmission fluid pressure SEN/SW A

Description

Using the engine load (throttle position), the primary pulley revolution speed, and the secondary pulley revolution speed as input signal, TCM changes the operating pressure of the primary pulley and the secondary pulley and changes the groove width of the pulley to control the gear ratio.

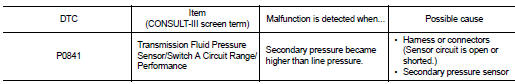

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch OFF. Then wait at least 10 seconds before performing the next test.

Perform the following procedure to confirm the malfunction is eliminated after the repair.

1.CHECK DTC DETECTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” in “TRANSMISSION”.

3. Start engine and maintain the following conditions for at least 12 consecutive seconds.

VEHICLE SPEED : 40 km/h (25 MPH) More than RANGE : “D” position

Is “P0841” detected? YES >> Go to TM-232, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

1.CHECK LINE PRESSURE

Perform line pressure test. Refer to TM-188, "Inspection and Judgment".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace damaged parts. Refer to TM-188, "Inspection and Judgment".

2.CHECK SECONDARY PRESSURE SENSOR SYSTEM

Check secondary pressure sensor system. Refer to TM-230, "DTC Logic".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK LINE PRESSURE SOLENOID VALVE

Check line pressure solenoid valve. Refer to TM-220, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK SECONDARY PRESSURE SOLENOID VALVE

Check secondary pressure solenoid valve. Refer to TM-226, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK STEP MOTOR

Check step motor. Refer to TM-251, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace damaged parts.

6.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

P0840 transmission fluid pressure SEN/SW A

P0840 transmission fluid pressure SEN/SW A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds befo ...

P0868 transmission fluid pressure

P0868 transmission fluid pressure

Description

The secondary pressure solenoid valve regulates the secondary pressure to

suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC C ...

Other materials:

B1122, B1123, B1124, B1125, B1126, B1127 diagnosis sensor unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Input shaft and gear

Exploded View

1. Input shaft front bearing

2. Input shaft

3. 3rd input gear

4. Spacer

5. Snap ring

6. 3rd baulk ring

7. 3rd-4th coupling sleeve

8. 3rd-4th synchronizer hub

9. Insert key

10. 4th baulk ring

11. 4th input gear

12. 5th input gear

13. 5th baulk ring

14. 5th-6th c ...

Three-point type seat belt

WARNING

• Every person who drives or rides in this vehicle should use a seat belt

at all times.

• Do not ride in a moving vehicle when the seatback is reclined. This can be dangerous.

The shoulder belt will not be against your body. In an accident, you could be thrown

into it and receive nec ...