Nissan Juke Service and Repair Manual : P0840 transmission fluid pressure SEN/SW A

DTC Logic

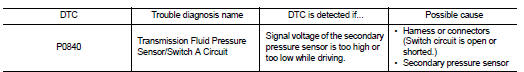

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE

:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” in “TRANSMISSION”.

3. Make sure that output voltage of line temperature sensor is within the range below.

ATF TEMP SEN : 1.0 – 2.0 V If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the voltage (cool down the fluid)

4. Start engine and wait for at least 5 consecutive seconds.

With GST

With GST

Follow the procedure “With CONSULT-III”.

Is “P0840” detected? YES >> Go to TM-230, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

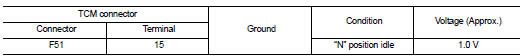

1.CHECK INPUT SIGNAL

1. Start engine.

2. Check voltage between TCM connector terminal and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 2.

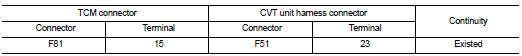

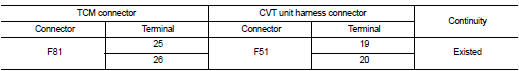

2.CHECK HARNESS BETWEEN TCM AND SECONDARY PRESSURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect TCM connector and CVT unit harness connector.

3. Check continuity between TCM connector terminal and CVT unit harness connector terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace damaged parts.

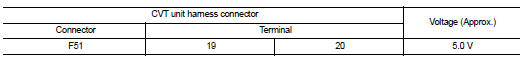

3.CHECK SENSOR POWER AND SENSOR GROUND

1. Connect TCM connector.

2. Turn ignition switch ON.

3. Check voltage between CVT unit harness connector terminals.

4. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4. CHECK HARNESS BETWEEN TCM AND CVT UNIT HARNESS CONNECTOR (SENSOR POWER AND SENSOR GROUND)

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

3. Check continuity between TCM connector terminals and CVT unit harness connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5. CHECK THE TCM SHORT

Replace same type TCM, perform self-diagnosis check. Erase self-diagnostic results and then start engine perform self-diagnosis check. Refer to TM-230, "DTC Logic".

Is “P0840” detected again? YES >> Replace the transaxle assembly. Refer to TM-301, "Removal and Installation".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

6.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

P0826 up and down shift SW

P0826 up and down shift SW

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignit ...

P0841 transmission fluid pressure SEN/SW A

P0841 transmission fluid pressure SEN/SW A

Description

Using the engine load (throttle position), the primary pulley revolution

speed, and the secondary pulley revolution

speed as input signal, TCM changes the operating pressure of the pri ...

Other materials:

LAN System can system (type 5)

DTC/CIRCUIT DIAGNOSIS

Main line between IPDM-E and DLC circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose

connection (connector s ...

Changing a flat tire

If you have a flat tire, follow the instructions below.

Stopping the vehicle

1. Safely move the vehicle off the road and away from traffic.

2. Turn on the hazard warning flashers.

3. Park on a level surface and apply the parking brake.

4. Continuously Variable Transmission (CVT) models:

Move t ...

Rear window defogger on signal

With auto A/C

WITH AUTO A/C : Description

Turns the indicator lamp in the rear window defogger switch ON when operating

the rear window defogger

WITH AUTO A/C : Component Function Check

1.CHECK REAR WINDOW DEFOGGER ON SIGNAL

Check that the indicator lamp of rear window defogger switch is illu ...