Nissan Juke Service and Repair Manual : Horn function

Component Function Check

1.CHECK FUNCTION 1

1. Disconnect vehicle security horn relay.

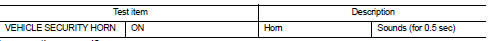

2. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM” using CONSULT- III.

3. Check the horn operation.

Is the operation normal? YES >> GO TO 2.

NO >> Go to SEC-225, "Diagnosis Procedure".

2.CHECK FUNCTION 2

1. Reconnect vehicle security horn relay.

2. Disconnect horn relay.

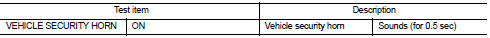

3. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM” using CONSULT- III.

4. Check the horn operation.

Is the operation normal? YES >> INSPECTION END

NO >> Go to SEC-225, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Perform inspection in accordance with procedure that confirms malfunction.

Which procedure confirms malfunction? Component Function Check 1>>GO TO 2.

Component Function Check 2>>GO TO 4.

2.CHECK HORN FUNCTION

Check that horn functions properly using horn switch.

Do horns sound? YES >> GO TO 3.

NO >> Check horn circuit. Refer to HRN-3, "Wiring Diagram".

3.CHECK HORN CONTROL CIRCUIT

1. Disconnect horn relay.

2. Disconnect IPDM E/R connector.

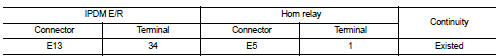

3. Check continuity between IPDM E/R harness connector and horn relay harness connector.

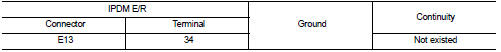

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

4.CHECK HORN FUNCTION

Check that vehicle security horn functions properly using horn switch.

Do horns sound? YES >> GO TO 5.

NO >> Check vehicle security horn circuit. Refer to HRN-3, "Wiring Diagram".

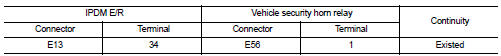

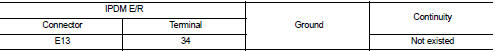

5.CHECK VEHICLE SECURITY HORN CONTROL CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and vehicle security horn relay harness connector.

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Hood switch

Hood switch

Component Function Check

1.CHECK FUNCTION

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indicati ...

Security indicator lamp

Security indicator lamp

Component Function Check

1.CHECK FUNCTION

1. Perform “THEFT IND” in the “ACTIVE TEST” mode of “BCM” using

CONSULT-III.

2. Check security indicator lamp operation.

Is the inspection result norm ...

Other materials:

Malfunction indicator

Component Function Check

1.CHECK MI FUNCTION

1. Turn ignition switch ON.

2. Make sure that MI lights up.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-1019, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK CAN COMMUNICATION LINE

Refer to LAN ...

Fuel injector

Component Function Check

1.INSPECTION START

Turn ignition switch to START.

Is any cylinder ignited?

YES >> GO TO 2.

NO >> Go to EC-778, "Diagnosis Procedure".

2.CHECK FUEL INJECTOR FUNCTION

With CONSULT-III

1. Start engine.

2. Perform “POWER BALANCE” in “ACTIVE T ...

P0720 output speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, p ...