Nissan Juke Service and Repair Manual : Hood switch

Component Function Check

1.CHECK FUNCTION

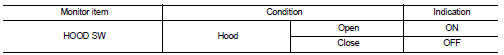

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indication normal? YES >> Hood switch is OK.

NO >> Go to SEC-155, "Diagnosis Procedure".

Diagnosis Procedure

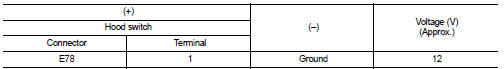

1.CHECK HOOD SWITCH SIGNAL CIRCUIT 1

1. Turn ignition switch OFF.

2. Disconnect hood switch connector.

3. Check voltage between hood switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

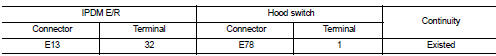

2.CHECK HOOD SWITCH SIGNAL CIRCUIT 2

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and hood switch harness connector

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation".

NO >> Repair or replace harness.

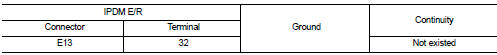

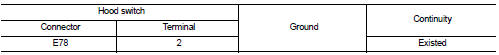

3.CHECK HOOD SWITCH GROUND CIRCUIT

Check continuity between hood switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK HOOD SWITCH

Refer to SEC-156, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace hood switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

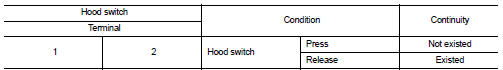

1.CHECK HOOD SWITCH

1. Turn ignition switch OFF.

2. Disconnect hood switch connector.

3. Check continuity between hood switch terminals

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace hood switch.

B2110 shift position/clutch interlock switch

B2110 shift position/clutch interlock switch

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B2110 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to PCS-

30, "DTC Logic".

DTC CONFIRMATION PROC ...

Horn function

Horn function

Component Function Check

1.CHECK FUNCTION 1

1. Disconnect vehicle security horn relay.

2. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM”

using CONSULT-

III.

3. ...

Other materials:

Fuel-filler cap

To remove the fuel-filler cap:

1. Turn the fuel-filler cap counterclockwise 1 to remove.

2. Put the fuel-filler cap on the cap holder A while refueling.

To install the fuel-filler cap:

1. Insert the fuel-filler cap straight into the fuelfiller tube.

2. Turn the fuel-filler cap clockwise 2 unt ...

B26F3 starter control relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B26F3 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B26F3 is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...

Off position warning does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&qu ...