Nissan Juke Service and Repair Manual : Horn function

Component Function Check

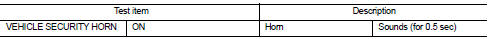

1.CHECK FUNCTION 1

1. Disconnect vehicle security horn relay.

2. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM” using CONSULT- III.

3. Check the horn operation.

Is the operation normal? YES >> GO TO 2.

NO >> Go to SEC-157, "Diagnosis Procedure".

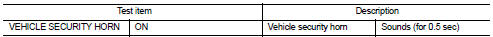

2.CHECK FUNCTION 2

1. Reconnect vehicle security horn relay.

2. Disconnect horn relay.

3. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM” using CONSULT- III.

4. Check the horn operation.

Is the operation normal? YES >> INSPECTION END

NO >> Go to SEC-157, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Perform inspection in accordance with procedure that confirms malfunction.

Which procedure confirms malfunction? Component Function Check 1>>GO TO 2.

Component Function Check 2>>GO TO 4.

2.CHECK HORN FUNCTION

Check that horn functions properly using horn switch.

Do horns sound? YES >> GO TO 3.

NO >> Check horn circuit. Refer to HRN-3, "Wiring Diagram".

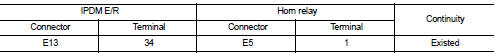

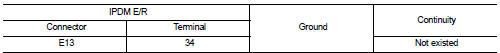

3.CHECK HORN CONTROL CIRCUIT

1. Disconnect horn relay.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and horn relay harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

4.CHECK HORN FUNCTION

Check that vehicle security horn functions properly using horn switch.

Do horns sound? YES >> GO TO 5.

NO >> Check vehicle security horn circuit. Refer to HRN-3, "Wiring Diagram".

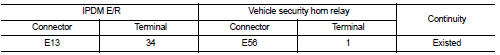

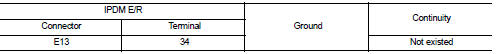

5.CHECK VEHICLE SECURITY HORN CONTROL CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and vehicle security horn relay harness connector.

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Hood switch

Hood switch

Component Function Check

1.CHECK FUNCTION

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indicati ...

Security indicator lamp

Security indicator lamp

Component Function Check

1.CHECK FUNCTION

1. Perform “THEFT IND” in “ACTIVE TEST” mode of “IMMU” of “BCM” using

CONSULT-III.

2. Check security indicator lamp operation.

Is the inspection resul ...

Other materials:

Front wiper motor hi circuit

Component Function Check

1.CHECK FRONT WIPER HI OPERATION

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Hi : Front wiper (HI) operation

Off : Stop the front wiper

Is front wiper (HI) operation normal ...

P0090 fuel pump

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK HIGH PRESSURE SUPPLY PUMP (PRESSURE CONTROL VALVE) POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect high pressure supply pump (pressure control valve) harness

connector.

3. Turn ignition switch ON.

4. Check the voltage betwe ...

Liquid Gasket

REMOVAL OF LIQUID GASKET

• After removing mounting nuts and bolts, separate the mating surface

using the seal cutter [SST: KV10111100] (A) and remove old

liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap the seal cutter [SST: KV10111100] to insert it (B), an ...