Nissan Juke Service and Repair Manual : Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger switch signal, etc.) is transferred via the CAN communication line.

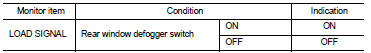

Component Function Check

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Select “LOAD SIGNAL” and check indication as per the following conditions.

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to EC-418, "Diagnosis Procedure".

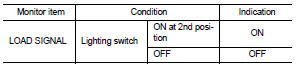

2.CHECK LIGHTING SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

Check “LOAD SIGNAL” indication as per the following conditions.

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to EC-418, "Diagnosis Procedure".

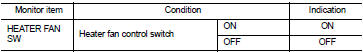

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

Select “HEATER FAN SW” and check indication as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-418, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-418, "Component Function Check".

Which circuit is related to the incident? Rear window defogger>>GO TO 2.

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Check the rear window defogger system. Refer to DEF-25, "Work Flow".

>> INSPECTION END 3.CHECK HEADLAMP SYSTEM

Check the headlamp system. Refer to EXL-43, "Work Flow".

>> INSPECTION END 4.CHECK HEATER FAN CONTROL SYSTEM

Check the heater fan control system. refer to HA-72, "Work Flow".

>> INSPECTION END

Ignition signal

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES >> GO TO 2.

NO >> Proceed to EC-414, "Diagnosis Procedure ...

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FAN DUTY CONTROL” in “ACTIVE TEST” mode of “ENGINE” using

CONSULT-III.

3. Check th ...

Other materials:

Removal and Installation

REMOVAL

1. Separate the rear propeller shaft. Refer to DLN-121, "Removal and

Installation".

2. Remove right side drive shaft. Refer to FAX-24, "RIGHT SIDE : Removal and

Installation".

3. Remove catalyst convertor support bracket (RH). EM-35, "4WD : Removal and

Insta ...

B210E starter relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B210E is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

PCS-30, "DTC Logic".

• If DTC B210E is displayed with DTC B2605, first perform the trouble diagnosis

for DTC B2605. Refer to

SEC-90, "D ...

Precautions

Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

• After removing mounting nuts and bolts, separate the mating surface

using the seal cutter [SST: KV10111100 (J-37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap the seal cutter [SS ...