Nissan Juke Service and Repair Manual : Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FAN DUTY CONTROL” in “ACTIVE TEST” mode of “ENGINE” using CONSULT-III.

3. Check that cooling fan speed varies according to the percentage.

Without CONSULT-III

Without CONSULT-III

1. Activate IPDM E/R auto active test and check cooling fan motors operation. Refer to PCS-12, "Diagnosis Description".

2. Check that cooling fan operates.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-420, "Diagnosis Procedure".

Diagnosis Procedure

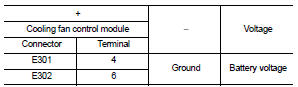

1.CHECK COOLING FAN CONTROL MODULE POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect cooling fan control nodule harness connector.

3. Turn ignition switch ON.

4. Check the voltage between cooling fan control nodule harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 2.

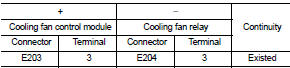

2.CHECK COOLING FAN CONTROL MODULE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect cooling fan relay harness connector.

3. Check the continuity between cooling fan control nodule harness connector and cooling fan relay harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

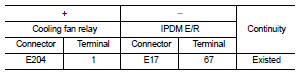

3.CHECK COOLING FAN RELAY POWER SUPPLY CIRCUIT

1. Disconnect IPDM E/R harness connector.

2. Check the continuity between cooling fan relay harness connector and IPDM E/R harness connector.

3. Also check harness for short to ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK COOLING FAN RELAY

Check cooling fan relay. Refer to EC-422, "Component Inspection (Cooling Fan Relay)".

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Replace cooling fan relay. Refer to PG-7, "Standardized Relay".

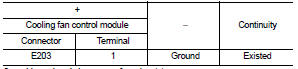

5.CHECK COOLING FAN CONTROL MODULE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check the continuity between cooling fan control nodule harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

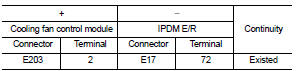

6.CHECK COOLING FAN CONTROL SIGNAL CIRCUIT

1. Disconnect IPDM E/R harness connector.

2. Check the continuity between cooling fan control nodule harness connector and IPDM E/R harness connector.

3. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

7.CHECK COOLING FAN CONTROL MODULE OUTPUT SIGNAL CIRCUIT

1. Reconnect all harness connectors disconnected.

2. Disconnect cooling fan control module harness connector.

3. Turn ignition switch ON.

4. Check the voltage between cooling fan control module terminals and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK COOLING FAN MOTORS -1 AND -2

Check the cooling fan motor. Refer to EC-422, "Component Inspection (Cooling Fan Motor)".

YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace cooling motor. Refer to CO-20, "Exploded View".

Component Inspection (Cooling Fan Motor)

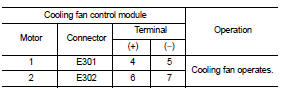

1.CHECK COOLING FAN MOTOR

1. Turn ignition switch OFF.

2. Disconnect cooling fan control module harness connector.

3. Supply cooling fan control module harness connector terminals with battery voltage as per the following, and check operation.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunctioning cooling fan motor. Refer to CO-20, "Exploded View".

Component Inspection (Cooling Fan Relay)

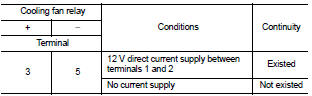

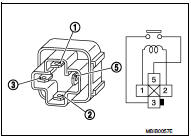

1.CHECK COOLING FAN RELAY

1. Turn ignition switch OFF.

2. Remove cooling fan relay.

3. Check the continuity between cooling fan relay terminals under the following conditions

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace cooling fan relay. Refer to PG-7, "Standardized Relay".

Electrical load signal

Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger

switch signal, etc.) is transferred via

the CAN communication line.

Component Function Check

1.CHECK REAR WIN ...

Refrigerant pressure sensor

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check ...

Other materials:

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation of each part. Check that any s ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

Diagnosis and repair work flow

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an

interview utilizing DLN-37, "Diagnostic

Work Sheet" and reproduce symptoms as well as fully understand it. Ask customer

about his/her complaints

carefully. ...