Nissan Juke Service and Repair Manual : Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

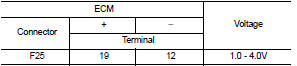

3. Check the voltage between ECM harness connector and ground.]

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-423, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY

1. Turn ignition OFF.

2. Disconnect refrigerant pressure sensor harness connector.

3. Turn ignition switch ON.

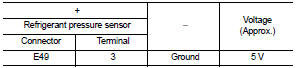

4. Check the voltage between refrigerant pressure sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

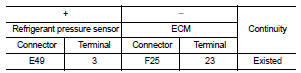

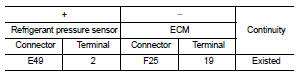

3. Check the continuity between refrigerant pressure sensor harness connector and ECM harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK REFRIGERANT PRESSURE SENSOR GROUND

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

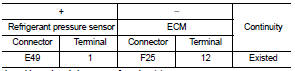

3. Check the continuity between refrigerant pressure sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between ECM harness connector and refrigerant pressure sensor harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK INTERMITTENT INCIDENT.

Perform GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace refrigerant pressure sensor. Refer to HAC-96, "Exploded View".

NO >> Repair or replace error-detected parts.

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FAN DUTY CONTROL” in “ACTIVE TEST” mode of “ENGINE” using

CONSULT-III.

3. Check th ...

Brake pedal position switch

Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. C ...

Other materials:

B2602 shift position

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2602 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2602 is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...

Periodic maintenance

STEERING WHEEL

Inspection

STEERING WHEEL AXIAL END PLAY

1. Check installation conditions of steering gear assembly, front suspension

assembly, axle and steering column

assembly.

2. Check if movement exists when steering wheel is moved up and down, to the

left and right and to the axial

dir ...

Cooler pipe and hose

Exploded View

1. A/C unit assembly

2. O-ring

3. High-pressure pipe

4. O-ring

5. Low-pressure flexible hose

6. High-pressure flexible hose

7. O-ring

8. Condenser

9. Compressor

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

High-pressure flexible hose : Removal and Installa ...