Nissan Juke Service and Repair Manual : Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

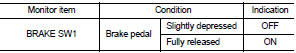

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Check “BRAKE SW1” indication as per the following conditions.

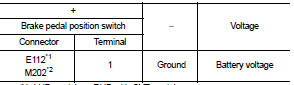

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-425, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect brake pedal position switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between brake pedal position switch harness connector and ground.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is the inspection result normal? YES >> GO TO 2.

NO >> Perform the trouble diagnosis for power supply circuit.

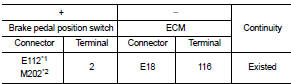

2.CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between brake pedal position switch harness connector and ECM harness connector.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

4. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK BRAKE PEDAL POSITION SWITCH

Check the brake pedal position switch. Refer to EC-426, "Component Inspection (Brake Pedal Position Switch)" Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View" (LHD) or BR-88, "Exploded View" (RHD)

Component Inspection (Brake Pedal Position Switch)

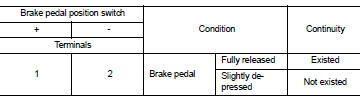

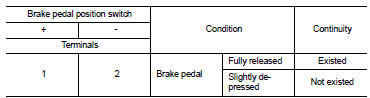

1.CHECK BRAKE PEDAL POSITION SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect brake pedal position harness connector.

3. Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH-II

1. Adjust brake pedal position switch installation. Refer to BR-9, "Inspection and Adjustment" (LHD) or BR- 77, "Inspection and Adjustment" (RHD).

2. Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View" (LHD) or BR-88, "Exploded View" (RHD).

Refrigerant pressure sensor

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check ...

Clutch pedal position switch

Clutch pedal position switch

Component Function Check

1.CHECK FOR CLUTCH PEDAL POSITION SWITCH FUNCTION

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result nor ...

Other materials:

B257B, B257C ambient sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC is displayed along with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to HAC-

275, "DTC Logic".

• If DTC is displayed along with DTC U1010, first perform the trouble diagnosis

for DTC U1010. HAC-276,

"DTC Log ...

Event Data Recorders (EDR)

This vehicle is equipped with an Event Data Recorder (EDR). The main purpose

of an EDR is to record, in certain crash or near crash-like situations, such as

an air bag deployment or hitting a road obstacle, data that will assist in understanding

how a vehicle’s systems performed.

The EDR is d ...

Engine oil

Inspection

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check the engine oil level.

If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and check that the engine ...