Nissan Juke Service and Repair Manual : Clutch pedal position switch

Component Function Check

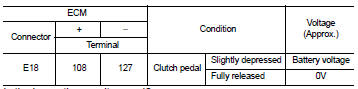

1.CHECK FOR CLUTCH PEDAL POSITION SWITCH FUNCTION

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> INSPECTION END.

NO >> Proceed to EC-427, "Diagnosis Procedure".

Diagnosis Procedure

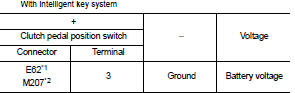

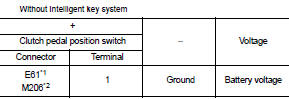

1.CHECK CLUTCH PEDAL POSITION INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect clutch pedal position switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between clutch pedal position switch harness connector and ground.

*1: LHD models

*2: RHD models

*1: LHD models

*2: RHD models

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

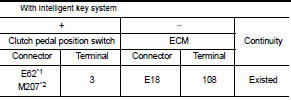

2.CHECK CLUTCH PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connectors.

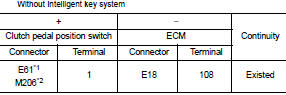

3. Check the continuity between clutch pedal position switch harness connector and ECM harness connector.

*1: LHD models

*2: RHD models

*1: LHD models

*2: RHD models

4. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK CLUTCH PEDAL POSITION SWITCH GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connectors.

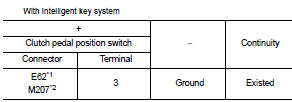

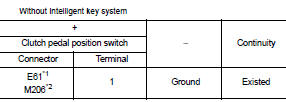

3. Check the continuity between clutch pedal position switch harness connector and ground

*1: LHD models

*2: RHD models

*1: LHD models

*2: RHD models

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK CLUTCH PEDAL POSITION SWITCH

Check the clutch pedal position switch. Refer to EC-429, "Component Inspection".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace clutch pedal position switch. Refer to CL-16, "LHD : Exploded View" (LHD models) or CL- 18, "RHD : Exploded View" (RHD models).

Component Inspection

1.CHECK CLUTCH PEDAL POSITION SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect clutch pedal position switch harness connector.

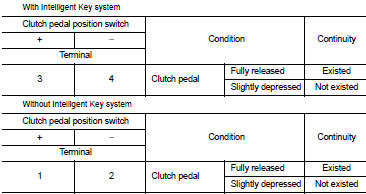

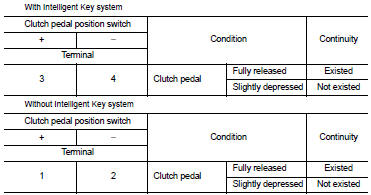

3. Check the continuity between clutch pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK CLUTCH PEDAL POSITION SWITCH-II

1. Adjust clutch pedal position switch installation. Refer to CL-17, "LHD : Inspection and Adjustment" (LHD models) or CL-19, "RHD : Inspection and Adjustment" (RHD models).

2. Check the continuity between clutch pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace clutch pedal position switch. Refer to CL-16, "LHD : Exploded View" (LHD models) or CL- 18, "RHD : Exploded View" (RHD models).

Brake pedal position switch

Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. C ...

ASCD main switch

ASCD main switch

Component Function Check

1.CHECK ASCD MAIN SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “MAIN SW” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Check “MAIN SW ...

Other materials:

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...

Camshaft valve clearance

Valve Clearance

CHECKING AND ADJUSTING THE VALVE CLEARANCE

1. Install the tappet.

2. Install the camshaft.

3. Install the camshaft brackets.

: 11 N·m (1.1 kg-m, 8 ft-lb)

4. Place the valves of the cylinder concerned at the “end of

exhaust - beginning of inlet” position and check the clearance ...

Push-button ignition switch position indicator

Description

Push-button ignition switch changes the power supply position.

BCM maintains the power supply position status.

BCM changes the power supply position with the operation of the push-button

ignition switch.

Component Function Check

1.CHECK FUNCTION

Check push-button ignition swi ...