Nissan Juke Service and Repair Manual : Catalyst

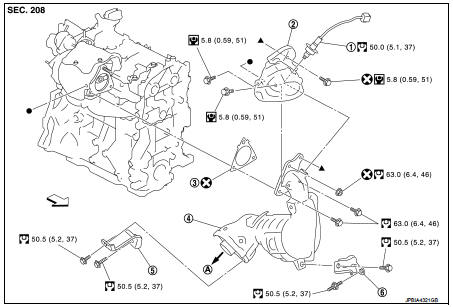

2WD

2WD : Exploded View

1. A/F sensor 1

2. Catalyst convertor shroud upper

3. Gasket

4. Catalyst

5. Catalyst convertor support bracket rear

6. Catalyst convertor bracket (RH)

A. To exhaust system

: Engine front

: Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

2WD : Removal and Installation

REMOVAL

1. Remove engine cover. Refer to EM-25, "Exploded View".

2. Remove cowl top extension. Refer to EXT-20, "Exploded View".

3. Remove front tube. Refer to EX-5, "Exploded View".

4. Remove A/F sensor 1.

• Using heated oxygen sensor wrench [SST: KV10117100], remove A/F sensor 1.

CAUTION:

Handle A/F sensor 1 carefully and avoid impacts.

5. Remove catalyst convertor shroud upper.

6. Remove bolts and nut of catalyst convertor turbocharger side.

7. Remove support bracket (RH).

8. Remove drive shaft insulator. Refer to 9. Remove catalyst convertor.

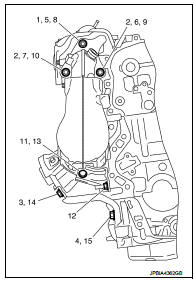

INSTALLATION

1. Install catalyst convertor with the following procedure.

• Tighten in numerical order as shown in the figure.

- Install catalyst convertor (base on stud position 1).

- Temporary assemble 2 (no priority).

- Temporary assemble 3, 4.

- Tightening 5, 6 and 7.

- Tightening again 8, 9 and 10.

- Temporary assemble 11.

- Tightening 12,13,14,and 15.

2. Install in the reverse order of removal after this step.

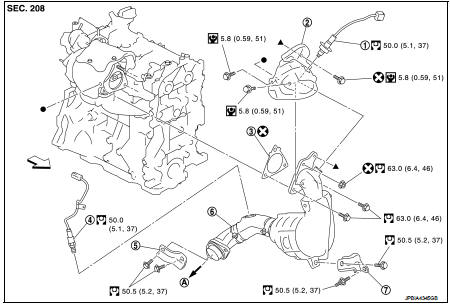

4WD

4WD : Exploded View

1. A/F sensor 1

2. Catalyst convertor shroud upper

3. Gasket

4. Heated oxygen sensor 2

5. Catalyst convertor upport bracket rear

6. Catalyst convertor

7. Catalyst convertor support bracket (RH)

A. To exhaust system

Engine front

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

4WD : Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-11, "Draining".

2. Remove engine cover. Refer to EM-25, "Exploded View".

3. Remove cowl top extension. Refer to EXT-20, "Exploded View".

4. Remove front tube. Refer to EX-5, "Exploded View" 5. Remove A/F sensor 1.

6. Remove catalyst convertor shroud upper.

7. Remove bolts and nut of catalyst convertor turbocharger side.

8. Remove drive shaft insulator.

9. Remove support bracket (RH).

10. Move catalyst convertor.

11. Remove turbocharger. Refer to EM-36, "Exploded View".

12. Remove catalyst convertor.

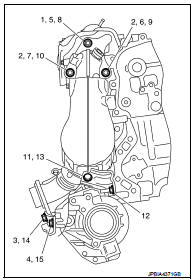

INSTALLATION

1. Install catalyst convertor with the following procedure.

• Tighten in numerical order as shown in the figure.

- Install catalyst convertor (base on stud position 1).

- Temporary assemble 2 (no priority).

- Temporary assemble 3, 4.

- Tightening 5, 6 and 7.

- Tightening again 8, 9 and 10.

- Temporary assemble 11.

- Tightening 12,13,14,and 15.

2. Install in the reverse order of removal after this step.

Charge air cooler

Charge air cooler

Exploded View

1. Air inlet tube assembly

2. Air inlet tube bracket

3. Clamp

4. Air inlet hose

5. Gasket

6. Turbocharger

7. Mounting rubber

8. Charge air cooler

9. Air inlet tube assem ...

Turbocharger

Turbocharger

Exploded View

1. Heat insulator

2. Actuator hose

3. Clamp

4. Turbocharger inlet tube

5. Gasket

6. Gasket

7. Clamp

8. Oil outlet hose

9. Oil return pipe

10. Oil supply tube

11. O-ri ...

Other materials:

Brake pedal

Inspection and Adjustment

INSPECTION

Brake Pedal Height

Check the height (H1) between the dash lower panel (1) and the

brake pedal upper surface.

H1 : Refer to BR-70, "Brake Pedal".

CAUTION:

Remove the floor trim.

Stop Lamp Switch

Check the clearance (C) among the brake pedal le ...

C1155 brake fluid level switch

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

P245A EGR cooler bypass valve control solenoid valve

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P245A is displayed with DTC P0560 or P0657, first perform trouble

diagnosis for DTC P0560 or P0657.

Refer to EC-963, "DTC Logic" (DTC P0560) or EC-976, "DTC Logic" (DTC P0657).

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

...