Nissan Juke Service and Repair Manual : Turbocharger

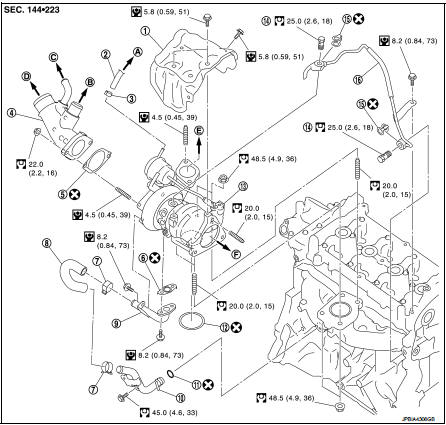

Exploded View

1. Heat insulator

2. Actuator hose

3. Clamp

4. Turbocharger inlet tube

5. Gasket

6. Gasket

7. Clamp

8. Oil outlet hose

9. Oil return pipe

10. Oil supply tube

11. O-ring

12. O-ring

13. Turbocharger

14. Eye bolt

15. Gasket

16. Oil supply tube

A. To EVAP canister purge volume control

solenoid valve

B. To air inlet hose

C. To PCV hose

D. To air duct E. To air inlet tube assembly F. To catalyst convertor

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-11, "Draining".

2. Remove engine cover. Refer to EM-25, "Exploded View".

3. Remove air cleaner cover assembly and air cleaner body assembly. Refer to EM-26, "Exploded View".

4. Remove air inlet tube assembly. Refer to EM-31, "Exploded View".

5. Remove cowl top extension. Refer to EXT-20, "Exploded View".

6. Disconnect heated oxygen sensor 2 harness connector.

7. Remove front tube. Refer to EX-5, "Exploded View".

8. Remove catalyst convertor. Refer to EM-33, "2WD : Exploded View" (2WD models) or EM-34, "4WD : Exploded View" (4WD models).

9. Remove turbocharger assembly as follows:

a. Remove heat insulator.

b. Remove oil supply tube.

c. Remove mounting nuts of turbocharger.

CAUTION:

Be careful not to deform each turbocharger piping when pulling out the assembly.

INSTALLATION

Install in the reverse order of removal.

NOTE

:

Apply LOCTITE FRENETANCH or equivalent to the threads of the turbocharger oil inlet pipe union to the cylinder head

Inspection

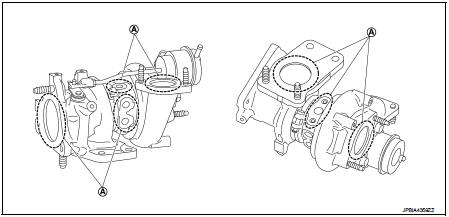

Turbocharger

A. Check for leakage

CAUTION:

When the compressor wheel, turbine wheel or rotor shaft is damaged, remove all

the fragments and

foreign matter left in the following passages in order to prevent a secondary

failure:

Suction side : Between turbocharger and air cleaner Exhaust side : Between turbocharger and outlet duct

INSPECTION AFTER INSTALLATION

Start engine and raise engine speed to check no exhaust emission leaks.

Catalyst

Catalyst

2WD

2WD : Exploded View

1. A/F sensor 1

2. Catalyst convertor shroud upper

3. Gasket

4. Catalyst

5. Catalyst convertor support bracket rear

6. Catalyst convertor bracket (RH)

A. To exhau ...

Exhaust manifold

Exhaust manifold

Exploded View

1. Stud bolt

2. Exhaust manifold cover

3. Exhaust manifold

4. Gasket

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every

disassembly.

Remova ...

Other materials:

A/C switch

Component Function Check

1.CHECK A/C ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “AIR COND SW” in “DATA MONITOR” mode, and check status under the

following condition.

Is the inspection result normal?

YES >> ...

Service Notice or Precaution

OBD SELF-DIAGNOSIS (WITH OBD)

• CVT self-diagnosis is performed by the TCM in combination with the ECM. The

results can be read through

the blinking pattern of the malfunction indicator (MI). Refer to the table on

TM-159, "CONSULT-III Function

(TRANSMISSION)" for the indicator used ...

C1121, C1123, C1125, C1127 ABS out valve system

DTC Logic

DTC DETECTION LOGIC

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ABS”.

Is DTC “C1121”, “C1123”, “C1125” or “C1127” detected?

YES > ...