Nissan Juke Service and Repair Manual : Water pump

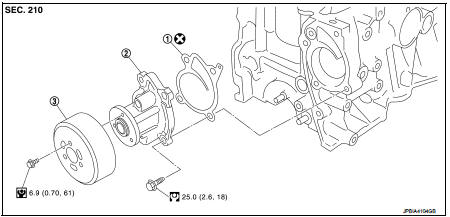

Exploded View

1. Gasket

2. Water pump

3. Water pump pulley

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-37, "Draining".

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belt.

2. Steer front wheel to the right.

3. Remove front fender protector (RH). Refer to EXT-22, "Removal and Installation".

4. Loosen mounting bolts of water pump pulley before loosening belt tension of drive belt.

5. Remove drive belt. Refer to EM-160, "Removal and Installation".

6. Remove water pump pulley.

7. Remove water pump.

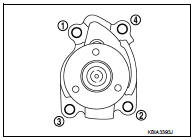

• Loosen mounting bolts in reverse order as shown in the figure.

• Engine coolant will leak from cylinder block, so have a receptacle ready below.

CAUTION:

• Handle water pump vane so that it does not contact any

other parts.

• Water pump cannot be disassembled and should be replaced as a unit.

INSTALLATION

Install in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

• Check visually that there is no significant dirt or rusting on water pump body and vane (A).

• Check that there is no looseness in vane shaft, and that it turns smoothly when rotated by hand.

• Replace water pump, if necessary.

INSPECTION AFTER INSTALLATION

• Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the radiator cap tester (commercial service tool). Refer to CO-37, "Inspection".

• Start and warm up the engine. Check visually that there is no leakage of engine coolant.

Cooling fan

Cooling fan

Exploded View

1. Fan motor

2. Fan shroud

3. Cooling fan

A. Apply on fan motor shaft

: Apply genuine high strength

thread locking sealant or equivalent.

: N·m (kg-m, in-lb)

Removal and In ...

Thermostat

Thermostat

Exploded View

1. Radiator hose (upper)

2. Water inlet

3. Rubber ring

4. Thermostat

A. To radiator

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

Removal and Installation

...

Other materials:

B2612 steering status

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2612 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2612 is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...

Three-point type seat belt

WARNING

• Every person who drives or rides in this vehicle should use a seat belt

at all times.

• Do not ride in a moving vehicle when the seatback is reclined. This can be dangerous.

The shoulder belt will not be against your body. In an accident, you could be thrown

into it and receive nec ...

B1132 side air bag module RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...