Nissan Juke Service and Repair Manual : Vacuum lines

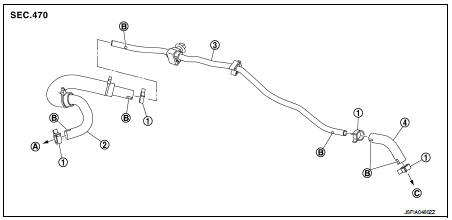

MR16DDT : Exploded View

1. Clamp

2. Vacuum hose A

3. Vacuum piping

4. Vacuum hose B

A. To engine side

B. Paint mark C. To brake booster

MR16DDT : Removal and Installation

REMOVAL

1. Remove air duct and air cleaner case. Refer to EM-161, "Removal and Installation".

2. Remove the vacuum hose and vacuum piping.

3. Perform inspection after removal. Refer to BR-49, "MR16DDT : Inspection".

INSTALLATION

Note the following, install the vacuum hose.

• When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown in the figure.

CAUTION:

Never use lubricating oil during assembly.

A : 24 mm (0.95 in) or mor

- Face the paint mark of vacuum hose A (engine side) upward to assemble.

- Face the other paint marks to vehicle front side to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR- 49, "MR16DDT : Exploded View".

MR16DDT : Inspection

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

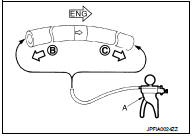

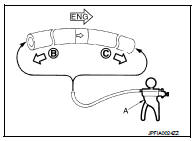

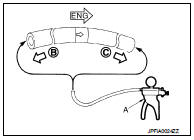

Check Valve Airtightness • Use a handy vacuum pump (A) to check.

When connected to the booster side (B): Vacuum should decrease within 1.3 kPa (9.8 mmHg, 0.38 inHg, 0.013 bar) for 15 seconds under a vacuum of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C): Vacuum should not exist.

• Replace vacuum hose if vacuum hose is malfunctioning.

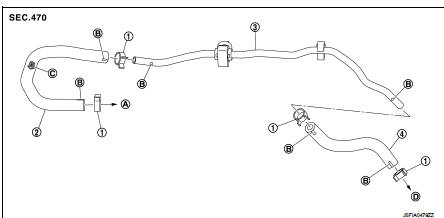

HR16DE : Exploded View

1. Clamp

2. Vacuum hose (built-in check valve)

3. Vacuum piping

4. Vacuum hose

A. To intake manifold

B. Paint mark

C. Stamp indicating engine direction

D. To brake booster

HR16DE : Removal and Installation

REMOVAL

1. Remove air duct and air cleaner case. Refer to EM-161, "Removal and Installation".

2. Remove the vacuum hose and vacuum piping.

3. Perform inspection after removal. Refer to BR-51, "HR16DE : Inspection".

INSTALLATION

Note the following, install the vacuum hose

• When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown in the figure.

CAUTION:

Never use lubricating oil during assembly.

A : 24 mm (0.95 in) or more

- Face the paint mark of vacuum hose (built-in check valve, intake manifold side) upward to assemble.

- Face the other paint marks to vehicle front side to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR- 50, "HR16DE : Exploded View".

HR16DE : Inspection

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness • Use a handy vacuum pump (A) to check.

When connected to the booster side (B): Vacuum should decrease within 1.3 kPa (9.8 mmHg, 0.38 inHg, 0.013 bar) for 15 seconds under a vacuum of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C): Vacuum should not exist.

• Replace vacuum hose assembly if vacuum hose and check valve are malfunctioning.

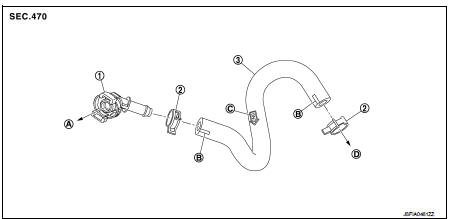

K9K : Exploded View

1. Connector

2. Clamp

3. Vacuum hose (built-in check valve)

A. To vacuum pump

B. Paint mark

C. Stamp indicating engine direction

D. To brake booster

K9K : Removal and Installation

REMOVAL

1. Remove air duct and air cleaner case. Refer to EM-161, "Removal and Installation".

2. Remove the vacuum hose and connector.

3. Perform inspection after removal. Refer to BR-52, "K9K : Inspection".

INSTALLATION

Note the following, install the vacuum hose.

• When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown in the figure.

CAUTION:

Never use lubricating oil during assembly.

A : 24 mm (0.95 in) or more

- Face the paint mark of vacuum hose (built-in check valve, connector side) to the vehicle left side to assemble.

- Face the paint mark of vacuum hose (built-in check valve, brake booster side) to the front side to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR- 51, "K9K : Exploded View".

K9K : Inspection

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness • Use a handy vacuum pump (A) to check.

When connected to the booster side (B): Vacuum should decrease within 1.3 kPa (9.8 mmHg, 0.38 inHg, 0.013 bar) for 15 seconds under a vacuum of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C): Vacuum should not exist.

• Replace vacuum hose assembly if vacuum hose and check valve are malfunctioning.

Brake booster

Brake booster

Exploded View

2WD

1. Master cylinder assembly

2. Vacuum pipe

3. Brake booster

4. Lock nut

5. Clevis

6. Gasket

7. Spacer

: N·m (kg-m, ft-lb)

4WD

1. Master cylinder assembly

2. Brak ...

Front disc brake

Front disc brake

Brake pad : Exploded View

MR16DDT

1. Cylinder body

2. Inner shim

3. Inner pad (with pad wear sensor)

4. Pad retainer

5. Torque member

6. Outer pad

7. Outer shim

1: Apply MOLYKOTE® AS880 ...

Other materials:

Clutch master cylinder

LHD : Exploded View

1. Reservoir hose

2. Reservoir tank

3. Master cylinder

LHD : Removal and Installation

REMOVAL

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

• Never disassemb ...

Engine oil

Inspection

OIL LEVEL AND MUDDINESS

• Before starting the engine, check the oil level placing vehicle

horizontally.

If the engine is already started, stop it and allow 10 minutes

before checking.

• Make sure the oil level is within the range shown in the figure.

• If it is out of range, adj ...

Exterior and interior lights

: See a NISSAN dealer for replacement.

NOTE: Always check with the Parts Department at a NISSAN dealer for the latest

information about parts.

: REMOVE

: INSTALL

Replacement procedures

All other lights are either type A, B, C, D or E.

When replacing a bulb, first remove the lens and/or c ...