Nissan Juke Service and Repair Manual : Structure and operation

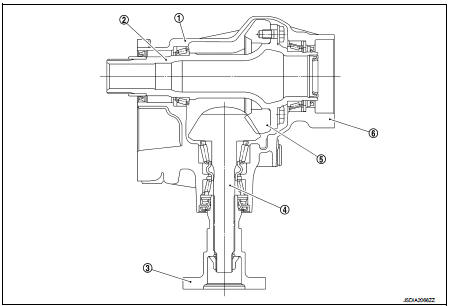

Sectional View

1. Transfer cover

2. Ring gear shaft

3. Companion flange

4. Drive pinion

5. Ring gear

6. Transfer case

Operation Principle

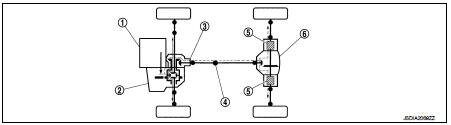

POWER TRANSFER DIAGRAM

1. Engine

2. Transaxle

3. Transfer

4. Propeller shaft

5. Electric controlled coupling

6. Rear final drive

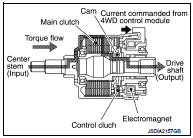

ELECTRIC CONTROLLED COUPLING

1. The 4WD control module supplies command current to each electric controlled coupling (4WD solenoid).

2. Each of control clutch is engaged by electromagnet and torque is detected in control clutch.

3. The cam operates in response to control clutch torque and applies pressure to main clutch.

4. Each of main clutch transmits torque to right and left rear wheels according to pressing power.

NOTE

:

Change each pressing power according to 4WD mode atatus

and cornering conditions

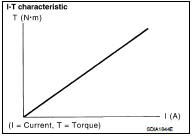

• Transmission torque to the right and left rear wheels is determined according to command current.

Component parts

Component parts

Component Parts Location

LHD models

1. ABS actuator and electric unit (control

unit)

Refer to BRC-97, "Component Parts

Location".

2. ECM

Refer to EC-25, "ENGINE CONTROL

SYSTEM ...

System

System

4WD system : System Diagram

INPUT/OUTPUT SIGNAL

It transmits/receives each signal from the following 4WD control module via

CAN communication line.

4WD system : System Description

• 4WD mo ...

Other materials:

Body component parts

Underbody Component Parts (2WD Models)

: Both sided anti-corrosive

precoated steel sections

: High strength steel (HSS)

sections

: Both sided anti-corrosive steel

and HSS sections

NOTE:

• For the parts without a number described in the figure, it is supplied only

with the assembly p ...

S terminal circuit

Description

The starter motor magnetic switch is supplied with power when the ignition

switch is turned to the START position

while the selector lever is in the P or N position for CVT models or the clutch

pedal is depressed for M/T

models.

Diagnosis Procedure

CAUTION:

Perform diagnosis un ...

Glow plug

Exploded View

1. Glow plug

Engine front

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

CAUTION:

Remove glow plug only if necessary. If carbon adheres, it may be stuck and

broken.

1. Disconnect the battery cable from the negative terminal.

2. Remove cowl top extension. Refer to EX ...