Nissan Juke Service and Repair Manual : Blower motor

Diagnosis Procedure

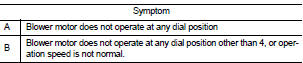

1.CHECK SYMPTOM

Check symptom (A or B).

Which symptom is detected? A >>GO TO 2.

B >>GO TO 7.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 15A fuses (Nos. 14 and 16, located in fuse block (J/B)].

NOTE

:

Refer to PG-22, "Fuse, Connector and Terminal Arrangement".

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

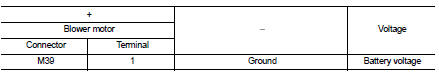

3.CHECK BLOWER MOTOR POWER SUPPLY

1. Disconnect blower motor connector.

2. Turn ignition switch ON.

3. Check voltage between blower motor harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK BLOWER RELAY

1. Turn ignition switch OFF.

2. Check blower relay. Refer to HAC-230, "Component Inspection (Blower Relay)".

Is the inspection result normal? YES >> Repair harness or connector between blower motor and fuse.

NO >> Replace blower relay.

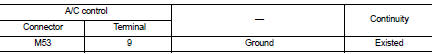

5.CHECK FAN SWITCH GROUND CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect A/C control connector.

3. Check continuity between A/C control harness connector and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair harness or connector.

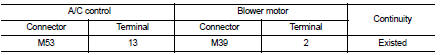

6.CHECK FAN SWITCH 4 POSITION CIRCUIT FOR OPEN Check continuity between A/C control harness connector and blower motor harness connector.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair the harness or connector.

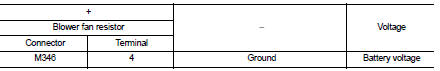

7.CHECK BLOWER FAN RESISTOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect blower fan resistor connector.

3. Turn ignition switch ON.

4. Check voltage between blower fan resistor harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair harness or connector between blower fan resistor and blower motor.

8.CHECK BLOWER FAN RESISTOR

1. Turn the ignition switch OFF.

2. Check blower fan resistor. Refer to HAC-230, "Component Inspection (Blower Fan Resistor)".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace blower fan resistor. Refer to HAC-242, "Removal and Installation".

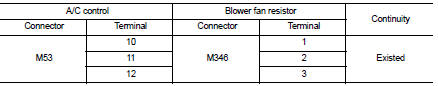

9.CHECK FAN SWITCH 1, 2, 3 POSITION CIRCUIT FOR OPEN

Check continuity between A/C control harness connector and blower fan resistor.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair harness or connector.

10.CHECK FAN SWITCH

Check fan switch. Refer to HAC-231, "Component Inspection (Fan Switch)".

Is the inspection result normal? YES >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

NO >> Replace A/C control. Refer to HAC-239, "Removal and Installation".

Component Inspection (Blower Motor)

1.CHECK BLOWER MOTOR

1. Remove blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

2. Check that there is not any mixing foreign object in the blower motor.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

2.CHECK BLOWER MOTOR

Check that there is not breakage or damage in the blower motor.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

3.CHECK BLOWER MOTOR

Check that blower motor turns smoothly.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

Component Inspection (Blower Relay)

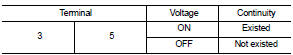

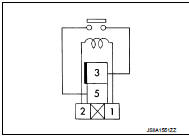

1.CHECK BLOWER RELAY

1. Remove blower relay. Refer to PG-22, "Fuse, Connector and Terminal Arrangement".

2. Check continuity between blower relay terminal 3 and 5 when the voltage is supplied between terminal 1 and 2.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower relay.

Component Inspection (Blower Fan Resistor)

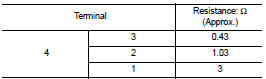

1.CHECK BLOWER FAN RESISTOR

1. Disconnect blower fan resistor connector.

2. Check resistance between blower fan resistor terminals. Refer to applicable table for the normal value.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower fan resistor. Refer to HAC-242, "Removal and Installation".

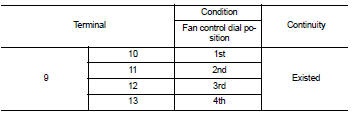

Component Inspection (Fan Switch)

1.CHECK FAN SWITCH

Check continuity between A/C control terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace A/C control. Refer to HAC-239, "Removal and Installation".

A/C indicator

A/C indicator

Diagnosis Procedure

1.CHECK SYMPTOM

Check symptom.

A/C indicator dose not turn ON>>GO TO 2.

A/C indicator dose not turn OFF>>GO TO 6.

2.CHECK FUSE

1. Turn ignition switch OFF.

...

Magnet clutch

Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis

Description" (with Intelligent Key) or PCS-

43, "Diagnosi ...

Other materials:

Keyfob battery

Exploded View

1. Upper case

2. Key

3. Switch cover

4. Switch rubber

5. Board surface

6. Battery

7. plate

8. Lower case

9. Screw

Removal and Installation

REMOVAL

1. Remove screw (9) on the rear of keyfob.

2. Place the key with the lower case (8) facing up. Set a screw-driver wrap ...

Drive belt auto tensioner and idler pulley

Exploded View

1. Front cover

2. Drive belt auto-tensioner

: N·m (kg-m, ft-lb)

Removal and Installation

Removal

1. Loosen mounting bolt and remove drive belt auto-tensioner.

Installation

Install in the reverse order of removal.

CAUTION:

When installing drive belt auto-tensioner, be c ...

General Precautions

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO2 fire

extinguisher.

• Never smoke while servicing fuel system. Keep open flames and sparks ...