Nissan Juke Service and Repair Manual : Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis Description" (with Intelligent Key) or PCS- 43, "Diagnosis Description" (without Intelligent Key).

Does it operate normally? YES >> INSPECTION END

NO >> Refer to HAC-232, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10A fuse (No. 49, located in IPDM E/R).

NOTE: Refer to PG-25, "Fuse, Connector and Terminal Arrangement".

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK MAGNET CLUTCH

1. Disconnect compressor connector.

2. Directly apply battery voltage to the magnet clutch. Check for operation visually and by sound.

Does it operate normally? YES >> GO TO 3.

NO >> Replace magnet clutch. Refer to HA-88, "MAGNET CLUTCH : Removal and Installation of Compressor Clutch".

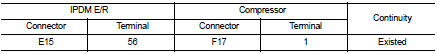

3.CHECK MAGNET CLUTCH POWER SUPPLY CIRCUIT FOR OPEN

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and compressor harness connector.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation" (with Intelligent Key) or PCS-63, "Removal and Installation" (without Intelligent Key).

NO >> Repair harness or connector.

Blower motor

Blower motor

Diagnosis Procedure

1.CHECK SYMPTOM

Check symptom (A or B).

Which symptom is detected?

A >>GO TO 2.

B >>GO TO 7.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 15A fuses ...

Other materials:

Unit removal and installation

Transaxle assembly

Exploded View

1. CVT fluid level gauge

2. CVT fluid charging pipe

3. O-ring

4. Transaxle assembly

5. Air breather hose

A. For tightening torque, refer to TM-301, "Removal and Installation".

Removal and Intallation

REMOVAL

WARNING:

Never remove the reservo ...

Terms

It is important to familiarize yourself with the following terms before loading

your vehicle: Х Curb Weight (actual weight of your vehicle) - vehicle weight

including: standard and optional equipment, fluids, emergency tools, and spare tire

assembly. This weight does not include passenge ...

S mode indicator

Component Function Check

1.CHECK S MODE INDICATOR FUNCTION

Check S mode indicator turns ON for approx. 2 seconds when ignition switch

turns ON.

Is the inspection results normal?

YES >> INSPECTION END

NO >> Go to TM-469, "Diagnosis Procedure".

Diagnosis Procedure

1.CH ...