Nissan Juke Service and Repair Manual : Basic inspection

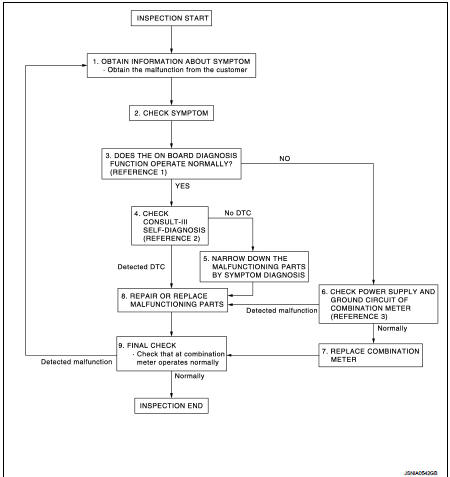

DIAGNOSIS AND REPAIR WORKFLOW (METER SYSTEM)

Work flow

OVERALL SEQUENCE

• Reference 1···MWI-22, "On Board Diagnosis Function".

• Reference 2···MWI-36, "DTC Index".

• Reference 3···MWI-51, "COMBINATION METER : Diagnosis Procedure".

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

• Check the symptom based on the information obtained from the customer.

• Check that any other malfunctions are present.

>> GO TO 3.

3.CHECK ON BOARD DIAGNOSIS OPERATION

Check that the on board diagnosis function operates. Refer to MWI-22, "On Board Diagnosis Function".

Does the on board diagnosis function operate normally? YES >> GO TO 4.

NO >> GO TO 6.

4.CHECK CONSULT-III SELF-DIAGNOSIS RESULTS

Connect CONSULT-III and perform self-diagnosis. Refer to MWI-36, "DTC Index".

Are self-diagnosis results normal? YES >> GO TO 5.

NO >> GO TO 8.

5.NARROW DOWN THE MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 8.

6.CHECK COMBINATION METER POWER SUPPLY AND GROUND CIRCUITS

Check combination meter power supply and ground circuits. Refer to MWI-51, "COMBINATION METER : Diagnosis Procedure".

Is inspection result OK? YES >> GO TO 7.

NO >> GO TO 8.

7.REPLACE COMBINATION METER

Replace combination meter.

>> GO TO 9.

8.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace the malfunctioning parts.

NOTE

:

If DTC is displayed, erase DTC after repair or replace malfunctioning parts.

>> GO TO 9.

9.FINAL CHECK

Check that the combination meter operates normally.

Do they operate normally? YES >> INSPECTION END

NO >> GO TO 1.

Wiring diagram

Wiring diagram

METER SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Info ...

Other materials:

Back door does not opened

Diagnosis Procedure

1.CHECK BACK DOOR OPENER SWITCH

Check back door opener switch.

Refer to DLK-69, "Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK BACK DOOR OPENER ACTUATOR

C ...

System

System Description

SYSTEM DIAGRAM

• The multi display unit transmits the operation status of the drive mode

switch to other units via CAN communication

as the mode signal (refer below).

- NORMAL: ON/OFF

- SPORT: ON/OFF

- ECO: ON/OFF

• Based on the mode signals received from TCM (CVT mod ...

Intelligent Key

Replace the battery in the Intelligent Key as follows: 1. Remove the mechanical

key from the Intelligent Key.

2. Insert a small screwdriver into the slit of the corner and twist it to separate

the upper part from the lower part. Use a cloth to protect the casing.

3. Replace the battery with ...