Nissan Juke Service and Repair Manual : B2555 stop lamp

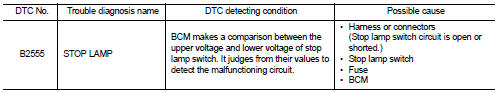

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Depress the brake pedal and wait 1 second or more.

2. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-73, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

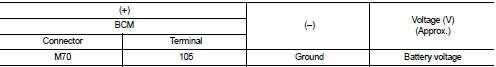

1.CHECK STOP LAMP SWITCH INPUT SIGNAL 1

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

Is the inspection normal? YES >> GO TO 2.

NO-1 >> Check 10 A fuse [No. 38, located in the fuse block (J/B)].

NO-2 >> Check harness for open or short between BCM and fuse.

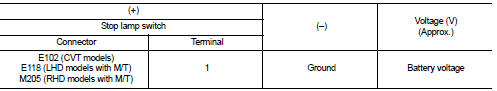

2.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Disconnect stop lamp switch connector.

2. Check voltage between stop lamp switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Check harness for open or short between stop lamp switch and fuse.

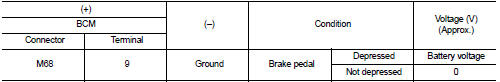

3.CHECK STOP LAMP SWITCH INPUT SIGNAL 2

1. Connect stop lamp switch connector.

2. Check voltage between BCM harness connector and ground.

Is the inspecting result normal? YES >> GO TO 4.

NO >> GO TO 5.

4.REPLACE BCM

1. Replace BCM. Refer to BCS-93, "Removal and Installation".

2. Perform initialization of BCM and registration of all Intelligent Keys using CONSULT-III.

For initialization and registration procedures, refer to CONSULT-III Operation Manual NATS-IVIS/NVIS.

>> INSPECTION END

5.CHECK STOP LAMP SWITCH CIRCUIT

1. Disconnect stop lamp switch connector.

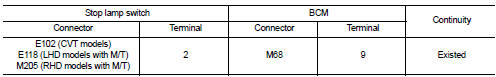

2. Check continuity between stop lamp switch harness connector and BCM harness connector.

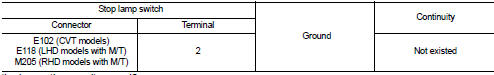

3. Check continuity between stop lamp switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.CHECK STOP LAMP SWITCH

Refer to SEC-74, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace stop lamp switch. Refer to BR-21, "Removal and Installation" (LHD) or BR-89, "Removal and Installation" (RHD).

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector.

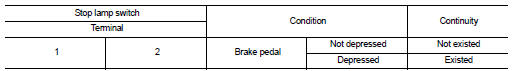

3. Check continuity between stop lamp switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace stop lamp switch. Refer to BR-21, "Removal and Installation" (LHD) or BR-89, "Removal and Installation" (RHD).

B2014 chain of STRG-IMMU

B2014 chain of STRG-IMMU

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Lock steering.

NOTE:

3. Press the push-button ignition switch.

4. Check DTC in “Self Diagn ...

B2556 Push-button ignition switch

B2556 Push-button ignition switch

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Press push-button ignition switch under the following condition.

- Brake pedal: Not depressed

2 ...

Other materials:

Door lock actuator

Driver side : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Door lock ...

P1651 starter motor relay

Description

ECM controls ON/OFF state of the starter relay, according to the engine and

vehicle condition. Models with no

Intelligent Key System transmit a control signal directly to IPDM E/R. On the

other hand, models with the Intelligent

Key System transmit a control signal to IPDM E/R by w ...

Unlock link function does not operate

Diagnosis Procedure

1.CHECK DRIVER SIDE OR PASSENGER SIDE DOOR SWITCH

Check driver side or passenger side door switch.

Refer to DLK-258, "Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

...