Nissan Juke Service and Repair Manual : Hoses

HOSE REMOVAL AND INSTALLATION

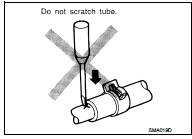

• To prevent damage to rubber hose, do not pry off rubber hose with tapered tool or screwdriver.

• To reinstall the rubber hose securely, check that hose insertion length and orientation is correct. (If tube is equipped with hose stopper, insert rubber hose into tube until it butts up against hose stopper.)

HOSE CLAMPING

• If old rubber hose is re-used, install hose clamp in its original position (at the indentation where the old clamp was). If there is a trace of tube bulging left on the old rubber hose, align rubber hose at that position.

• Discard old clamps; replace with new ones.

• After installing plate clamps, apply force to them in the direction of the arrow, tightening rubber hose equally all around.

Turbocharger (If Equipped)

Turbocharger (If Equipped)

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean supply

of oil flowing through the turbocharger and to follow all requi ...

Engine Oils

Engine Oils

Prolonged and repeated contact with used engine oil may cause skin cancer.

Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as s ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

Clutch pedal position switch

Component Function Check

1.CHECK FOR CLUTCH PEDAL POSITION SWITCH FUNCTION

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END.

NO >> Proceed to EC-427, "Diagnosis Procedure" ...

Cooling fan control

Cooling fan control : System Diagram

Cooling fan control : System Description

INPUT/OUTPUT SIGNAL CHART

*: The ECM determines the start signal status by the signals of engine speed

and battery voltage.

SYSTEM DESCRIPTION

ECM controls cooling fan speed corresponding to vehicle speed, eng ...