Nissan Juke Service and Repair Manual : System

Body control system

BODY CONTROL SYSTEM : System Description

OUTLINE

• BCM (Body Control Module) controls various electrical components.It receives the information required from CAN communication and the signals received from each switch and sensor.

• BCM has a combination switch reading function for reading the status of combination switches (light, turn signal, wiper and washer) in addition to functions for controlling the operation of various electrical components.

It also has a signal transmission function, for other systems, and a power consumption control function that reduces the power consumption with the ignition switch OFF.

• BCM is equipped with a diagnosis function that operates with CONSULT-III and allows for various settings to be changed.

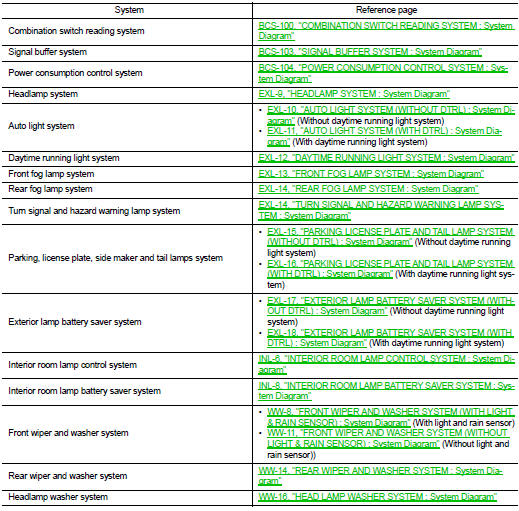

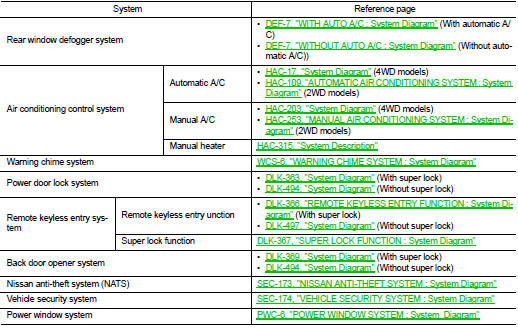

BCM FUNCTION LIST

BODY CONTROL SYSTEM : Fail-safe

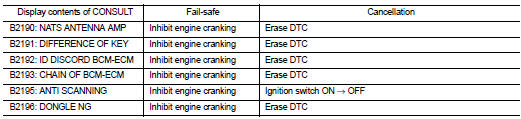

FAIL-SAFE CONTROL BY DTC

BCM performs fail-safe control when any DTC are detected.

REAR WIPER MOTOR PROTECTION

BCM detects the rear wiper stopping position according to the rear wiper auto stop signal.

When the rear wiper auto stop signal does not change more than 5 seconds while driving the rear wiper, BCM stops power supply to protect the rear wiper motor.

Condition of cancellation 1. Pass more than 1 minute after the rear wiper stop.

2. Turn rear wiper switch OFF.

3. Operate the rear wiper switch or rear washer switch.

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal lamp operating.

NOTE

:

The blinking speed is normal while activating the hazard warning lamp.

Combination switch reading system

COMBINATION SWITCH READING SYSTEM : System Diagram

NOTE

:

• *1: TAIL LAMP switch links lighting switch 1ST and 2ND positions.

• *2: “FR WIP INT/AT” is FR WIPER INT/AUTO.

COMBINATION SWITCH READING SYSTEM : System Description

OUTLINE

• BCM reads the status of the combination switch (light, turn signal, wiper and washer) and recognizes the status of each switch.

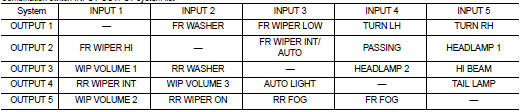

• BCM has a combination of 5 output terminals (OUTPUT 1 - 5) and 5 input terminals (INPUT 1 - 5). It reads a maximum of 20 switch status.

COMBINATION SWITCH MATRIX

Combination switch circuit

NOTE

:

• *1: TAIL LAMP switch links lighting switch 1ST and 2ND positions.

• *2: “FR WIP INT/AT” is FR WIPER INT/AUTO.

Combination switch INPUT-OUTPUT system list

NOTE

:

Headlamp has a dual system switch.

COMBINATION SWITCH READING FUNCTION

Description

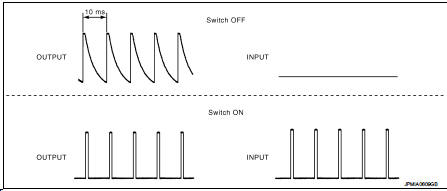

• BCM reads the status of the combination switch at 10 ms interval normally.

NOTE

:

BCM reads the status of the combination switch at 60 ms interval when BCM is

controlled at low power consumption

control mode.

• BCM operates as follows and judges the status of the combination switch.

- It operates the transistor on OUTPUT side in the following order: OUTPUT 1 → 2 → 3 → 4 → 5, and outputs voltage waveform.

- The voltage waveform of OUTPUT corresponding to the formed circuit is input into the interface on INPUT side if any (1 or more) switches are ON.

- It reads this change of the voltage as the status signal of the combination switch.

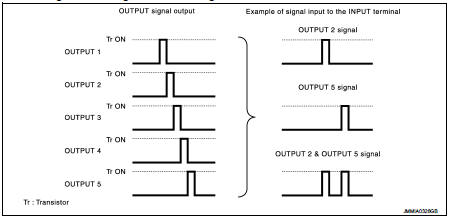

Operation Example

In the following operation example, the combination of the status signals of the

combination switch is replaced

as follows: INPUT 1 - 5 to “1 - 5” and OUTPUT 1 - 5 to “A - E”.

Example 1: When a switch (TAIL LAMP switch) is turned ON • The circuit between OUTPUT 4 and INPUT 5 is formed when the TAIL LAMP switch is turned ON.

• BCM detects the combination switch status signal “5D” when the signal of OUTPUT 4 is input to INPUT 5.

• BCM judges that the TAIL LAMP switch is ON when the signal “5D” is detected.

Example 2: When some switches (TURN RH switch, TAIL LAMP switch) are turned ON • The circuits between OUTPUT 1 and INPUT 5 and between OUTPUT 4 and INPUT 5 are formed when the TURN RH switch and TAIL LAMP switch are turned ON.

• BCM detects the combination switch status signal “5AD” when the signals of OUTPUT 1 and OUTPUT 4 are input to INPUT 5.

• BCM judges that the TURN RH switch and TAIL LAMP switch are ON when the signal “5AD” is detected.

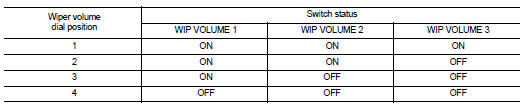

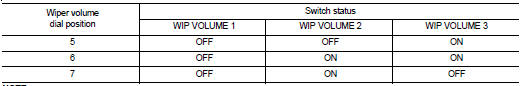

WIPER VOLUME DIAL POSITION

BCM judges the wiper volume dial 1 - 7 by the status of WIP VOLUME 1, 2 and 3 switches.

NOTE:

For details of wiper volume dial position, refer to WW-8, "FRONT WIPER AND WASHER SYSTEM (WITH LIGHT & RAIN SENSOR) : System Description" (with light and rain sensor), WW-11, "FRONT WIPER AND WASHER SYSTEM (WITHOUT LIGHT & RAIN SENSOR) : System Description" (without light and rain sensor).

Signal buffer system

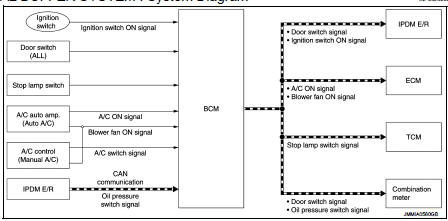

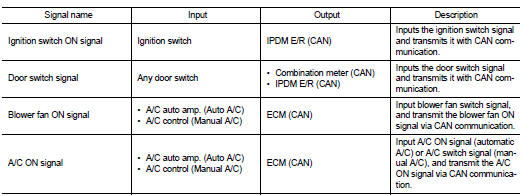

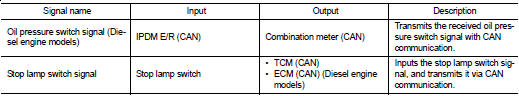

SIGNAL BUFFER SYSTEM : System Diagram

NOTE

:

Oil pressure switch is applied to diesel engine models.

SIGNAL BUFFER SYSTEM : System Description

OUTLINE

BCM has the signal transmission function that outputs/transmits each input/received signal to each unit.

SIGNAL TRANSMISSION FUNCTION LIST

Power consumption control system

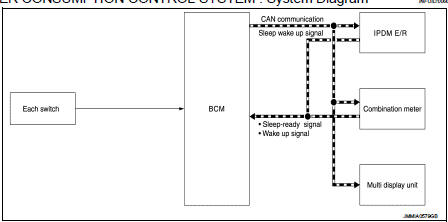

POWER CONSUMPTION CONTROL SYSTEM : System Diagram

POWER CONSUMPTION CONTROL SYSTEM : System Description

OUTLINE

• BCM incorporates a power saving control function that reduces the power consumption according to the vehicle status.

• BCM switches the status (control mode) by itself with the power saving control function. It performs the sleep request to each unit (IPDM E/R, combination meter and multi control unit) that operates with the ignition switch OFF.

Normal mode (wake-up)

- CAN communication is normally performed with other units

- Each control with BCM is operating properly

CAN communication sleep mode (CAN sleep) - CAN transmission is stopped - Control with BCM only is operating

Low power consumption mode (BCM sleep) - Low power consumption control is active - CAN transmission is stopped

LOW POWER CONSUMPTION CONTROL WITH BCM

BCM reduces the power consumption with the following operation in the low power consumption mode.

• The reading interval of the each switches changes from 10 ms interval to 60 ms interval.

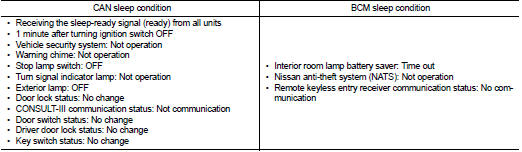

Sleep mode activation

• BCM receives the sleep-ready signal (ready) from IPDM E/R and combination

meter via CAN communication.

• BCM transmits the sleep wake up signal (sleep) to each unit when all of the CAN sleep conditions are fulfilled.

• Each unit stops the transmission of CAN communication with the sleep wake up signal. BCM is in CAN communication sleep mode.

• BCM is in the low power consumption mode and perform the low power consumption control when all of the BCM sleep conditions are fulfilled with CAN sleep condition.

Sleep condition

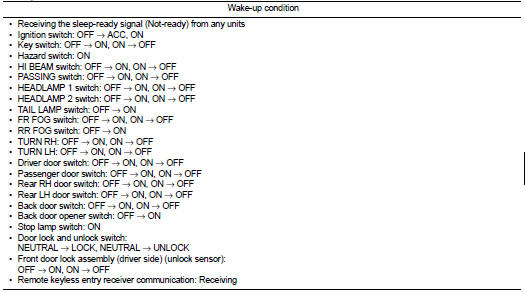

Wake-up operation

• BCM transmits sleep wake up signal (wake up) to each unit when any condition

listed below is established,

and then goes into normal mode from low power consumption mode.

• Each unit starts transmissions with CAN communication by receiving sleep wake up signals. Each unit transmit wake up signals to BCM with CAN communication to convey the start of CAN communication.

Wake-up condition

Component parts

Component parts

Body control system

BODY CONTROL SYSTEM : Component Parts Locatio

RHD MODELS

1. BCM

A. Behind of glove box (Left side)

LHD MODELS

1. BCM

A. Behind of instrument lower panel LH

(Left side)

...

Diagnosis system (BCM)

Diagnosis system (BCM)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perfo ...

Other materials:

Clutch pedal position switch

Component Function Check

1.CHECK FOR CLUTCH PEDAL POSITION SWITCH FUNCTION

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END.

NO >> Proceed to EC-427, "Diagnosis Procedure" ...

General maintenance

During the normal day-to-day operation of the vehicle, general maintenance should

be performed regularly as prescribed in this section. If you detect any unusual

sounds, vibrations or smell, be sure to check for the cause or have a NISSAN dealer

do it promptly. In addition, you should notify a ...

Cooling fan

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHE ...