Nissan Juke Service and Repair Manual : Cooling fan

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK COOLING FAN MOTOR CIRCUIT

1. Disconnect cooling fan motor harness connector.

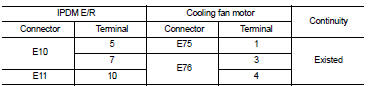

2. Check the continuity between IPDM E/R harness connector and cooling fan motor harness connector.

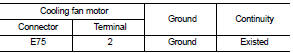

3. Check the continuity between cooling fan motor harness connector and ground.

4. Also check harness for short to ground and short to power.

YES or NO YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness for open or short between cooling fan motor and IPDM E/R • Harness for open or short between cooling fan motor and ground

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK COOLING FAN MOTOR

Refer to EC-1015, "Component Inspection".

YES or NO YES >> GO TO 5.

NO >> Replace cooling fan motor.

5.CHECK INTERMITTENT INCIDENT

Perform GI-42, "Intermittent Incident".

YES or NO YES >> Replace IPDM E/R. Refer to PCS-34, "Exploded View" (WITH I-KEY) or PCS-63, "Exploded View" (WITHOUT I-KEY).

NO >> Repair or replace harness or connector.

Component Inspection

1.CHECK COOLING FAN MOTOR

1. Turn ignition switch OFF.

2. Disconnect cooling fan motor harness connector E75 and E76.

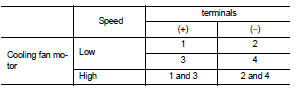

3. Supply cooling fan motor terminals with battery voltage and check operation.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace cooling fan motor.

CAN communication circuit

CAN communication circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Information display (ASCD)

Information display (ASCD)

Component Function Check

1.CHECK INFORMATION DISPLAY

1. Start engine.

2. Press ASCD MAIN switch.

3. Drive the vehicle at more than 30 km/h (20 MPH)

CAUTION:

Always drive vehicle at a safe speed. ...

Other materials:

Key positions

LOCK (0)

The key can only be removed from the ignition switch at this position.

OFF (1)

The engine is turned off. The power supply is turned off.

ACC (2)

The electrical accessory power activates without the engine turned on.

ON (3)

The ignition system and the electrical accessory power activa ...

Component parts

Component Parts Location

1. Push-button ignition switch

2. Stop lamp switch

Refer to BRC-9, "Component Parts

Location" (without EPS), BRC-97,

"Component Parts Location" (with

EPS)

3. IPDM E/R

Refer to PCS-5, "Component Parts

Location"

4. Transmission range ...

B2555 stop lamp

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Depress the brake pedal and wait 1 second or more.

2. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-73, "Diagnosis Procedu ...