Nissan Juke Service and Repair Manual : Electric ignition system

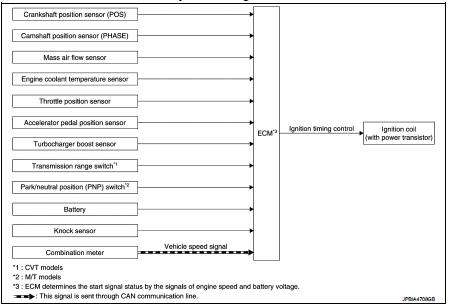

Electric ignition system : System Diagram

Electric ignition system : System Description

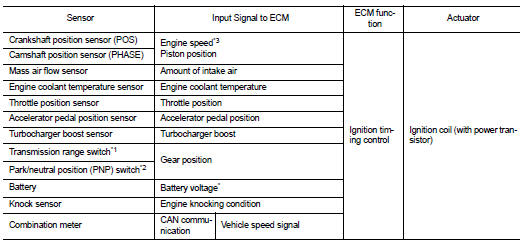

INPUT/OUTPUT SIGNAL CHART

*1: CVT models

*2: M/T models

*3: ECM determines the start signal status by the signals of engine speed and

battery voltage.

SYSTEM DESCRIPTION

Firing order: 1 - 3 - 4 - 2 The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor (PHASE) signal.

Computing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in the ECM.

• At starting

• During warm-up

• At idle

• At low battery voltage

• During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Fuel pressure control

Fuel pressure control

Fuel pressure control : System Diagram

Fuel pressure controlL : System Description

INPUT/OUTPUT SIGNAL CHART

*: ECM determines the start signal status by the engine speed signal and

battery v ...

Intake valve timing control

Intake valve timing control

Intake valve timing control : System Diagram

Intake valve timing control : System Description

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases co ...

Other materials:

Removal and installation

ALTERNATOR

HR16DE

HR16DE : Exploded View

REMOVAL

1. Alternator bracket mounting bolt

2. Alternator bracket

3. Alternator mounting bolt

4. Alternator

5. “B” terminal harness

6. “B” terminal nut

7. Alternator connector

: N·m (kg-m, ft-lb)

DISASSEMBLY

Type: A002TJ1291ZE

1. Rear be ...

Front grille

Exploded View

1. Bumper fascia assembly

2. Front side grille RH

3. Front center grille

4. Emblem

5. Front side grille LH

: Pawl

Removal and Installation

REMOVAL

CAUTION:

When remove front grilles (1) apply protective tape (A) on the

bumper fascia (2) to protect the painted surface fr ...

LAN System can system (type 7)

DTC/CIRCUIT DIAGNOSIS

Main line between IPDM-E and DLC circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose

connection (connector s ...