Nissan Juke Service and Repair Manual : B2198 nats antenna AMP.

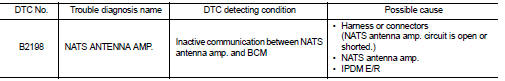

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE 1

1. Contact Intelligent Key backside to push-button ignition switch.

2. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-65, "Diagnosis Procedure".

NO >> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE 2

1. Press the push-button ignition switch.

2. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-65, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

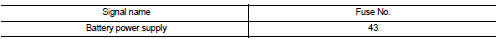

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check that the following fuse in IPDM E/R is not blown.

Is the fuse fusing? YES >> Replace the blown fuse after repairing the cause of blowing.

NO >> GO TO 2.

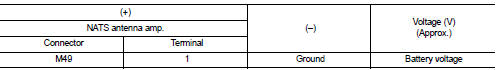

2.CHECK NATS ANTENNA AMP. POWER SUPPLY

1. Disconnect NATS antenna amp. connector.

2. Check voltage between NATS antenna amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

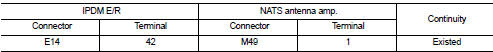

3.CHECK NATS ANTENNA AMP. POWER SUPPLY CIRCUIT

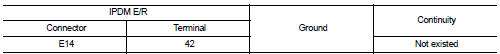

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and NATS antenna amp. connector.

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation".

NO >> Repair or replace harness.

4.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL 1

1. Connect NATS antenna amp. connector.

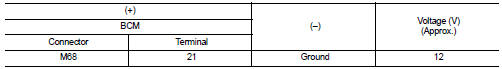

2. Disconnect BCM connector.

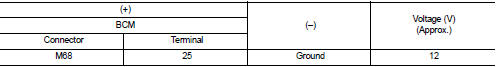

3. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL CIRCUIT 1

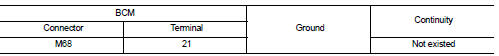

1. Disconnect NATS antenna amp. connector.

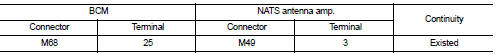

2. Check continuity between BCM harness connector and NATS antenna amp. connector.

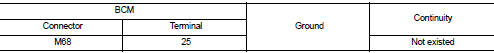

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

NO >> Repair or replace harness.

6.CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL 1

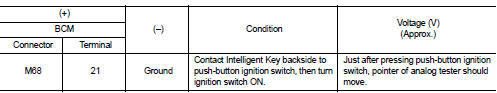

1. Connect BCM connector.

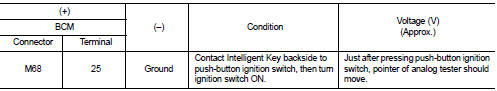

2. Check voltage between BCM harness connector and ground using analog tester.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

7.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL 2

1. Disconnect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 8.

8.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL CIRCUIT 2

1. Disconnect NATS antenna amp. connector.

2. Check continuity between BCM harness connector and NATS antenna amp. connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

NO >> Repair or replace harness.

9.CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL 2

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground using analog tester

Is the inspection result normal? YES >> GO TO 10.

NO >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

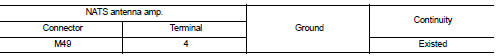

10.CHECK NATS ANTENNA AMP. GROUND CIRCUIT

1. Disconnect NATS antenna amp. connector.

2. Check continuity between NATS antenna amp. harness connector and ground.

Is the inspection result normal?

YES >> GO TO 11.

NO >> Repair or replace harness.

11.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

B2196 dongle unit

B2196 dongle unit

Description

BCM performs ID verification between BCM and dongle unit.

When verification result is OK, BCM permits cranking.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM ...

B2013 steering lock unit

B2013 steering lock unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Lock the steering.

NOTE:

3. Press the push-button ignition switch.

4. Check DTC in “Self D ...

Other materials:

B1153 curtain air bag module LH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Safety note

WARNING

• Do not disassemble or modify this system. If you do, it may result in accidents,

fire, or electric shock.

• Do not use this system if you notice any abnormality, such as a frozen screen

or lack of sound. Continued use of the system may result in accident, fire or electric

shock.

• ...

Diagnosis system (BCM)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...