Nissan Juke Service and Repair Manual : Brake fluid level switch

Component Function Check

1.CHECK BRAKE FLUID LEVEL SWITCH OPERATION

When the brake fluid is full or empty. Then check that the brake warning lamp in the combination meter turns ON/OFF correctly.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to BRC-72, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BRAKE FLUID LEVEL SWITCH CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect brake fluid level switch harness connector.

3. Disconnect combination meter harness connector.

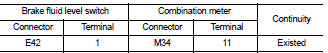

4. Check continuity between brake fluid level switch harness connector and combination meter harness connector.

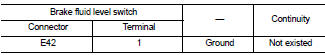

5. Check continuity between brake fluid level switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK BRAKE FLUID LEVEL SWITCH GROUND CIRCUIT

Check continuity between brake fluid level switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK BRAKE FLUID LEVEL SWITCH

Check brake fluid level switch. Refer to BRC-73, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace reservoir tank.

• LHD: Refer to BR-44, "Disassembly and Assembly".

• RHD: Refer to BR-109, "Disassembly and Assembly".

4.CHECK COMBINATION METER

Check combination meter. Refer to MWI-23, "CONSULT-III Function".

Is the inspection result normal?

YES >> Check each pin terminals for damage or loose connection with harness connector. If any items are damaged, repair or replace error-detected parts.

NO >> Repair or replace combination meter. Refer to MWI-69, "Removal and Installation".

Component Inspection

1.CHECK BRAKE FLUID LEVEL SWITCH

1. Turn the ignition switch OFF.

2. Disconnect brake fluid level switch harness connector.

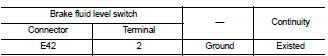

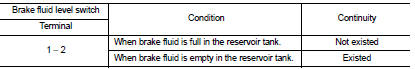

3. Check continuity between brake fluid level switch harness connector

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace reservoir tank.

• LHD: Refer to BR-44, "Disassembly and Assembly".

• RHD: Refer to BR-109, "Disassembly and Assembly".

Parking brake switch

Parking brake switch

Component Function Check

1.CHECK PARKING BRAKE SWITCH OPERATION

Operate the parking brake lever. Then check that the brake warning lamp in

the combination meter turns ON/

OFF correctly.

Is the ...

ABS warning lamp

ABS warning lamp

Component Function Check

1.CHECK ABS WARNING LAMP FUNCTION

Check that ABS warning lamp in combination meter turns ON for approx. 1

second after ignition switch is

turned ON.

CAUTION:

Never st ...

Other materials:

Eco information

CAUTION

Do not adjust the display controls while driving so that full attention may

given to vehicle operation.

The following ECO INFO mode will appear on the display by pushing the ECO information

button, then turning the selection dial to scroll through the different screens.

While driving, ...

Tail lamp circuit

Without daytime running light system

WITHOUT DAYTIME RUNNING LIGHT SYSTEM : Component Function

1.CHECK TAIL LAMP OPERATION

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2. With operating the test items, check that the tail lamp is turned ON.

TAIL : Tail Lamp ...

Commercial Service Tools

HFC-134a (R-134a) Service Tool and Equipment

• Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with

CFC-12 (R-12) refrigerant and/

or its lubricant.

• Separate and non-interchangeable service equipment must be used for handling

each type of refrigerant/

lubricant.

• R ...