Nissan Juke Service and Repair Manual : Unit disassembly and assembly

Torque converter and converter housing oil seal

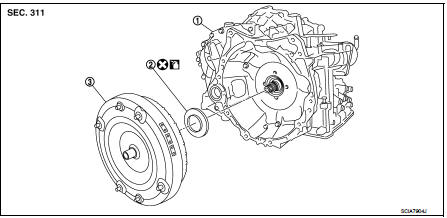

Exploded View

1. Transaxle assembly 2. Converter housing oil seal 3. Torque converter

: Always replace after every

: Always replace after every

disassembly.

: Apply CVT Fluid NS-2.

: Apply CVT Fluid NS-2.

Disassembly

1. Remove transaxle assembly. Refer to TM-301, "Removal and Installation".

2. Remove torque converter from transaxle assembly.

CAUTION:

Never damage bush on the inside of torque converter sleeve when removing torque

converter.

3. Remove converter housing oil seal using a flat-bladed screwdriver.

CAUTION:

Be careful not to scratch converter housing.

Assembly

Note the following, and install in the reverse order of removal.

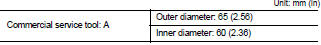

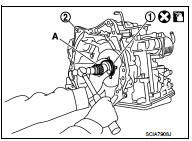

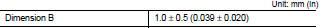

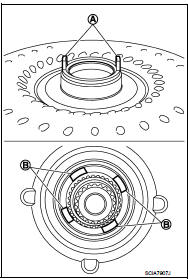

• Drive converter housing oil seal (1) evenly using a drift (A) (commercial service tool) so that converter housing oil seal protrudes by the dimension (B) respectively.

2 : Transaxle assembly

NOTE

:

Converter housing oil seal pulling direction is used as the reference.

• After completing installation, check for CVT fluid leakage and CVT fluid level. Refer to TM-184, "Inspection".

• Attach the pawl (A) of the torque converter to the drive sprocket hole (B) on the transaxle assembly side.

CAUTION:

• Rotate the torque converter for installing torque converter.

• Never damage the bushing inside the torque converter sleeve when installing the converter housing oil seal.

Inspection

INSPECTION AFTER INSTALLATION

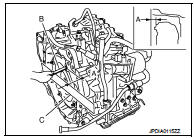

• After inserting a torque converter to the CVT, check dimension (A) with in the reference value limit.

B : Scale

C : Straightedge

Dimension (A) : Refer to TM-308, "Torque Converter".

Unit removal and installation

Unit removal and installation

Transaxle assembly

Exploded View

1. CVT fluid level gauge

2. CVT fluid charging pipe

3. O-ring

4. Transaxle assembly

5. Air breather hose

A. For tightening torque, refer to TM-301, "R ...

Other materials:

Air cleaner filter

Exploded View

1. Hose clamp

2. PCV hose

3. Hose clamp

4. Air cleaner filter

5. Air cleaner filter case

6. Grommet

7. Inlet Air duct (lower)

8. Grommet

9. Inlet Air duct (upper)

10. Bracket

11. Air cleaner case

12. O-ring

13. Mass air flow sensor

14. Air duct

A. To electric ...

Component parts

Component Parts Location

1. BCM

Refer to BCS-6, "BODY CONTROL

SYSTEM : Component Parts Location"

(With Intelligent Key system) or

BCS-96, "BODY CONTROL SYSTEM

: Component Parts Location"

(Without Intelligent Key system).

2. Rear window defogger connector

3. Rear windo ...

ECU diagnosis information

EPS control unit

Reference Value

VALUES ON THE DIAGNOSIS TOOL

CAUTION:

The output signal indicates the EPS control unit calculation data. The normal

values will be displayed

even in the event that the output circuit (harness) is open.

*1: Almost in accordance with the value of “MOTOR SIG”. ...