Nissan Juke Service and Repair Manual : Evap canister

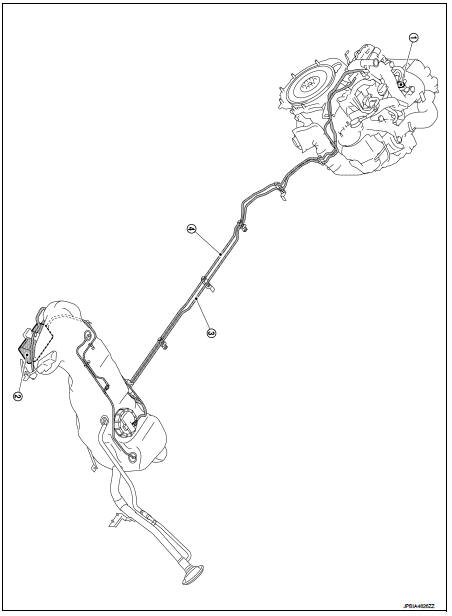

2WD : Hydraulic Layout

EVAPORATIVE EMISSION LINE DRAWING

1.EVAP canister purge volume control

solenoid valve

2. EVAP canister

3. EAVP line

4. Fuel line

NOTE

:

Do not use soapy water or any type of solvent while installing vacuum hose or

purge hoses.

2WD : Removal and Installation

REMOVAL

1. Disconnect EVAP canister hoses.

2. Remove EVAP canister fixing bolt.

3. Remove EVAP canister.

INSTALLATION

Install in the reverse order of removal.

NOTE

:

Tighten EVAP canister fixing bolt to the specified torque.

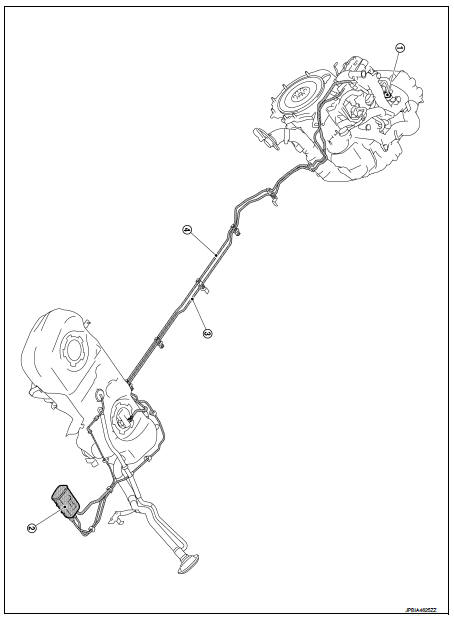

4WD : Hydraulic Layout

EVAPORATIVE EMISSION LINE DRAWING

1. EVAP service port

2. EVAP canister

3. EVAP line

4. Fuel line

NOTE

:

Do not use soapy water or any type of solvent while installing vacuum hose or

purge hoses.

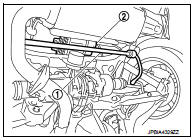

4WD : Removal and Installation

REMOVAL

1. Remove rear stabilizer (1). Refer to RSU-34, "Exploded View".

2. Disconnect EVAP canister hoses.

3. Remove EVAP canister fixing bolt.

4. Remove EVAP canister (2).

INSTALLATION

Install in the reverse order of removal.

NOTE

:

Tighten EVAP canister fixing bolt to the specified torque.

Fuel tank

Fuel tank

2WD : Exploded View

1. Fuel filler cap

2. Grommet

3. Fuel filler tube

4. EVAP canister hose

5. Fuel tank mounting band (RH)

6. Fuel tank mounting band (LH)

7. Fuel tank

8. Clamp

9. Fu ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Fuel Tank

Standard and Limit

...

Other materials:

System

WITH AUTO A/C

WITH AUTO A/C : System Diagram

WITH AUTO A/C : System Description

OPERATION DESCRIPTION

• BCM detects that the rear window defogger switch turns ON when the ignition

switch is ON, and then transmits

the rear window defogger switch signal to IPDM E/R via CAN communication for

...

Antenna base

Exploded View

1. Antenna rod

2. Antenna base

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

1. Remove headlining. Refer to INT-26, "Exploded View".

2. Disconnect antenna feeder connector.

3. Remove nut to remove antenna base.

INSTALLATION

Install in the reverse order o ...

P1632 fuel cut off valve

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK FUEL CUT OFF VALVE POWER SUPPLY CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect fuel cut off valve harness connector.

3. Turn ignition switch ON.

4. Check the voltage between fuel cut off valve harness connector ...