Nissan Juke Service and Repair Manual : U1000, U1001 CAN COMM CIRCUIT

Description

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle multiplex communication line with high data communication speed and excellent error detection ability. Many electronic control units are equipped onto a vehicle, and each control unit shares information and links with other control units during operation (not independent). In CAN communication, control units are connected with 2 communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

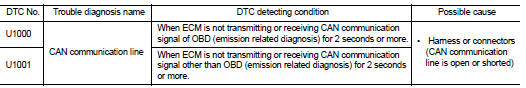

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 3 seconds.

2. Check DTC.

Is DTC detected? YES >> EC-569, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

Go to LAN-17, "Trouble Diagnosis Flow Chart".

Power supply and ground circuit

Power supply and ground circuit

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44,

"Circuit Inspection".

Is the i ...

P0011 IVT control

P0011 IVT control

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0011 is displayed with DTC P0075, first perform the trouble diagnosis

for DTC P0075. Refer to

EC-583, "DTC Logic".

DTC CONFIRMATION PROCE ...

Other materials:

EPS warning lamp does not turn on

Description

EPS warning lamp does not turn ON when turning ignition switch ON from OFF.

(Check the illumination of the

EPS warning lamp.)

Diagnosis Procedure

1.CHECK EPS WARNING LAMP

Perform the trouble diagnosis of EPS warning lamp. Refer to STC-26,

"Diagnosis Procedure".

Is t ...

Rear window defogger

Description

Heats the heating wire with the power supply from the rear window defogger

relay to prevent the rear window

from fogging up.

Component Function Check

1.CHECK FUNCTION

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the rear windo ...

P17BB primary pressure solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. S ...