Nissan Juke Service and Repair Manual : Power supply and ground circuit

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

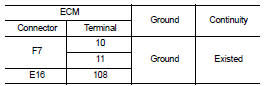

2.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connectors.

2. Check the continuity between ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F1 • Harness for open or short between ECM and ground

>> Repair open circuit or short to power in harness or connectors.

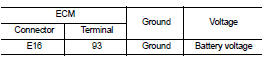

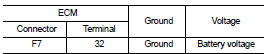

4.CHECK ECM POWER SUPPLY CIRCUIT-I

1. Reconnect ECM harness connectors.

2. Turn ignition switch ON.

3. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• 15 A fuse (No. 62)

• Harness for open or short between ECM and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

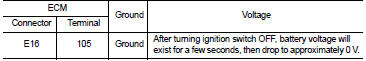

6.CHECK ECM POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON and then OFF.

Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 9.

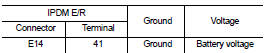

7.CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch ON.

2. Check the voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace IPDM E/R.

8.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

9.CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 13.

NO >> GO TO 10.

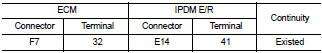

10.CHECK ECM POWER SUPPLY CIRCUIT-V

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E14.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 12.

NO >> GO TO 11.

11.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F1 • Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK 20 A FUSE

1. Disconnect 20 A fuse (No. 43) from IPDM E/R.

2. Check 20 A fuse.

Is the inspection result normal? YES >> GO TO 14.

NO >> Replace 20 A fuse.

13.CHECK ECM POWER SUPPLY CIRCUIT-VI

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E14.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 14.

NO >> Repair open circuit or short to ground or short power in harness or connectors.

14.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness or connectors.

Trouble diagnosis - specification valuE

Trouble diagnosis - specification valuE

Description

The specification (SP) value indicates the tolerance of the value that is

displayed in “SPEC” of “DATA MONITOR”

mode of CONSULT-III during normal operation of the Engine Control System ...

U1000, U1001 CAN COMM CIRCUIT

U1000, U1001 CAN COMM CIRCUIT

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Other materials:

Diagnosis and repair workflow

Work F

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurred) using the “Diagnostic Work Sheet”. (Refer to

EC-127, "Diagnostic Work

Sheet ...

Commercial Service Tools

HFC-134a (R-134a) Service Tool and Equipment

• Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with

CFC-12 (R-12) refrigerant and/

or its lubricant.

• Separate and non-interchangeable service equipment must be used for handling

each type of refrigerant/

lubricant.

• R ...

Tire Pressure Monitoring System (TPMS)

This vehicle is equipped with the Tire Pressure Monitoring System (TPMS). It

monitors tire pressure of all tires except the spare. When the low tire pressure

warning light is lit, and the CHECK TIRE PRES (pressure) warning message is displayed

in the vehicle information display, one or more of ...