Nissan Juke Service and Repair Manual : Turbocharger boost control

Turbocharger boost control : SystemDiagram

Turbocharger boost control : System Description

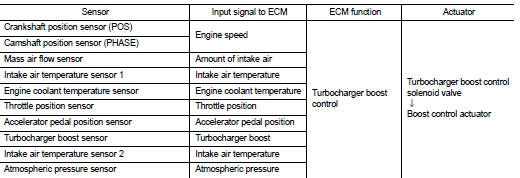

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

Depending on driving conditions, the ECM performs ON/OFF duty control of the turbocharger boost control solenoid valve and controls the boost by adjusting the pressure to the diaphragm of the boost control actuator.

When driving conditions demand an increase in boost, the ECM prolongs the ON time of the turbocharger boost control solenoid valve and moves the boost control valve towards the closing direction by reducing the pressure in the diaphragm of the boost control actuator. The emission gas to the turbine wheel is then increased. When driving conditions demand a decrease in boost, the ECM shortens the ON time of the turbocharger boost control solenoid valve and moves the boost control valve towards the opening position by increasing the pressure in the diaphragm of the boost control actuator. The emission bypassing to the turbine wheel is then increased. Thus, by performing the most optimal boost control, the ECM improves engine output and response.

NOTE

:

The boost varies depending on the vehicle and driving conditions.

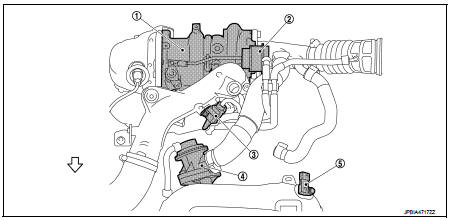

BOOST CONTROL ACTUATOR LINE DRAWING

1. Turbocharger

2. Boost control actuator

3. Turbocharger boost control solenoid

valve

4. Recirculation valve

5. Turbocharger boost sensor

(with intake air temperature sensor 2)

: Vehicle front

: Vehicle front

Exhaust valve timing control

Exhaust valve timing control

Exhaust valve timing control : System Diagram

Exhaust valve timing control: System Description

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases c ...

Engine protection control at low engine oil pressure

Engine protection control at low engine oil pressure

Engine protection control at low engine oil pressure : System Diagram

Engine protection control at low engine oil pressure : System Description

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

• ...

Other materials:

Door switch

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR SW-DR”, “DOOR SW-AS”, “DOOR SW-RL”, “DOOR SW-RR”, “BACK DOOR SW”

in

“DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the ...

C1111 ABS motor, motor relay system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

P0720 output speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

> ...