Nissan Juke Service and Repair Manual : Super lock actuator

Driver side

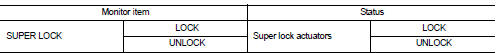

DRIVER SIDE : Component Function Check

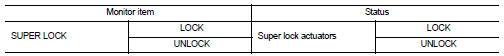

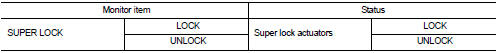

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Super lock actuator is OK.

NO >> Refer to DLK-407, "DRIVER SIDE : Diagnosis Procedure".

DRIVER SIDE : Diagnosis Procedure

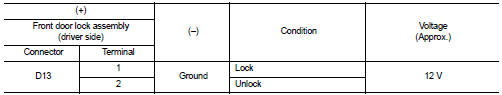

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check voltage between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal? YES >> Replace front door lock assembly (driver side).

NO >> GO TO 2.

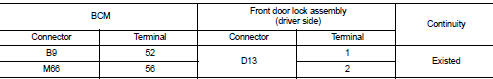

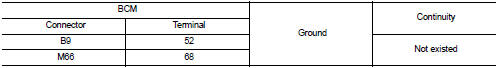

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

2. Check continuity between BCM harness connector and front door lock assembly (driver side) harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

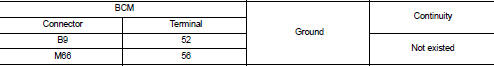

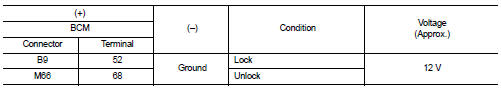

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

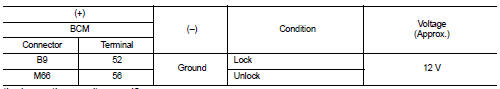

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Passenger side

PASSENGER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Super lock actuator is OK.

NO >> Refer to DLK-408, "PASSENGER SIDE : Diagnosis Procedure".

PASSENGER SIDE : Diagnosis Procedure

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (passenger side) connector.

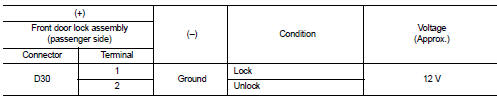

3. Check voltage between front door lock assembly (passenger side) harness connector and ground.

Is the inspection result normal? YES >> Replace front door lock assembly (passenger side).

NO >> GO TO 2.

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

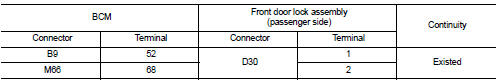

2. Check continuity between BCM harness connector and front door lock assembly (passenger side) harness connector

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Rear LH

REAR LH : Component Function Check

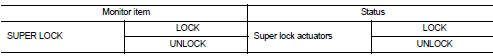

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Super lock actuator is OK.

NO >> Refer to DLK-409, "REAR LH : Diagnosis Procedure".

REAR LH : Diagnosis Procedure

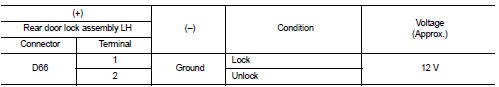

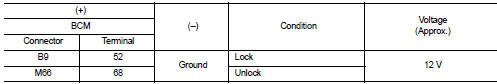

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear door lock assembly LH connector.

3. Check voltage between rear door lock assembly LH harness connector and ground.

Is the inspection result normal? YES >> Replace rear door lock assembly LH.

NO >> GO TO 2.

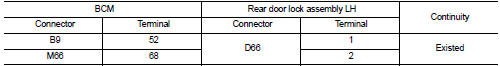

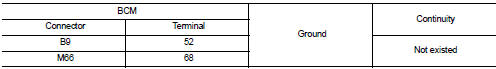

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

2. Check continuity between BCM harness connector and rear door lock assembly LH harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Rear RH

REAR RH : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Back door lock actuator is OK.

NO >> Refer to DLK-411, "REAR RH : Diagnosis Procedure".

REAR RH : Diagnosis Procedure

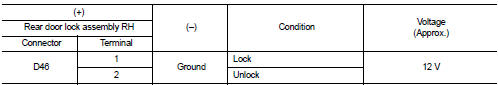

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear door lock assembly RH connector.

3. Check voltage between rear door lock assembly RH harness connector and ground.

Is the inspection result normal? YES >> Replace rear door lock assembly RH.

NO >> GO TO 2.

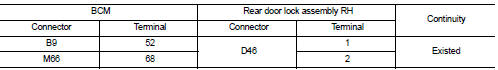

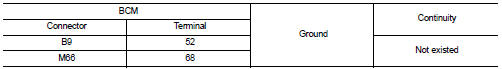

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

2. Check continuity between BCM harness connector and rear door lock assembly RH harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

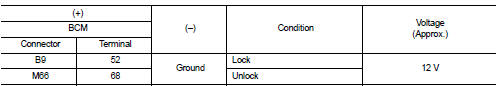

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Remote keyless entry receiver

Remote keyless entry receiver

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “KEYLESS ” or “KEYLESS UNLOCK” in “DATA MONITOR” mode.

3. Check that the function operates nor ...

Unlock sensor

Unlock sensor

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “LOCK STATUS” in “DATA MONITOR” mode.

3. Check that the function operates normally according t ...

Other materials:

C1109 power and ground system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

Cruise control operations

1. ACCEL/RES switch

2. COAST/SET switch

3. CANCEL switch

4. MAIN (ON·OFF) switch

The cruise control allows driving at a speed between 25 to 89 MPH (40 to 144

km/h) without keeping your foot on the accelerator pedal.

To turn on the cruise control, push the MAIN switch on. The CRUISE indicato ...