Nissan Juke Service and Repair Manual : Unlock sensor

Component Function Check

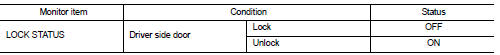

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “LOCK STATUS” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Unlock sensor is OK.

NO >> Refer to DLK-412, "Diagnosis Procedure".

Diagnosis Procedure

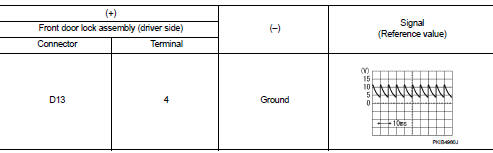

1.CHECK BCM OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check signal between front door lock assembly (driver side) harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

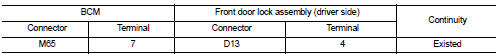

2.CHECK UNLOCK SENSOR CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and front door lock assembly (driver side) harness connector.

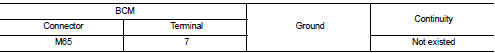

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-161, "Removal and Installation".

NO >> Repair or replace harness.

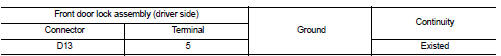

3.CHECK UNLOCK SENSOR GROUND CIRCUIT

Check continuity between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK UNLOCK SENSOR

Refer to DLK-413, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace front door lock assembly (driver side).

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

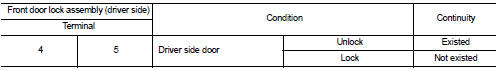

1.CHECK UNLOCK SENSOR

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check continuity between front door lock assembly (driver side) terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace front lock assembly (driver side).

Super lock actuator

Super lock actuator

Driver side

DRIVER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function oper ...

Other materials:

Operating range for engine start function

The Intelligent Key can only be used for starting the engine when the Intelligent

Key is within the specified operating range1 .

When the Intelligent Key battery is almost discharged or strong radio waves are

present near the operating location, the Intelligent Key system’s operating range

...

Diagnosis system (BCM)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...

C1115 wheel sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...