Nissan Juke Service and Repair Manual : Spark plug

Exploded View

1. Rocker cover protector

2. O-ring

3. PCV valve

4. PCV hose

5. Clamp

6. Rocker cover gasket

7. Rocker cover

8. Clamp

9. PCV hose

10. Oil filler cap

11. Spark plug

12. Ignition coil

A. To air duct assembly B. Tightening must be done following the installation procedure.

Refer to EM-53

C. To intake manifold

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

1. Remove engine cover. Refer to EM-25, "Exploded View".

2. Remove air inlet tube assembly. Refer to EM-31, "Exploded View".

3. Remove ignition coil.

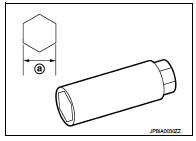

4. Remove spark plug with a spark plug wrench (commercial service tool).

a : 14 mm (0.55 in)

CAUTION:

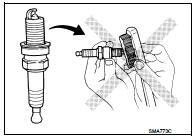

Never drop or shock spark plug.

INSTALLATION

Install in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

Spark plug (Standard type) : Refer to EM-129, "Spark Plug".

CAUTION:

• Never drop or shock spark plug.

• Never use a wire brush for cleaning.

• If plug tip is covered with carbon, spark plug cleaner may be used.

Cleaner air pressure : Less than 588 kPa (6 kg/cm2,

85 psi)

Cleaning time : Less than 20 seconds

• Spark plug gap adjustment is not required between replacement intervals.

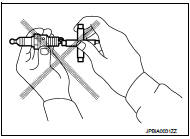

• Measure spark plug gap. when it exceeds the limit, replace spark plug even if it is with in the specified replacement mileage.

Refer to EM-129, "Spark Plug".

Air cleaner filter

Air cleaner filter

Removal and Installation

REMOVAL

1. Remove air duct assembly (duct side) (1).

2. Unhook the tabs (A) of both ends of the air cleaner cover.

3. Remove the air cleaner filter (1) and air cleaner b ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

Oil pan (lower)

Exploded View

1. O-ring

2. Oil pan (upper)

3. Oil level gauge guide

4. O-ring

5. Oil level gauge

6. Oil pump drive chain

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump chain tensioner

10. Oil pump

11. Drain plug

12. Drain plug washer

13. Oil pan (lower)

14. Oil fil ...

Diagnosis system (BCM)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...