Nissan Juke Service and Repair Manual : Thermostat

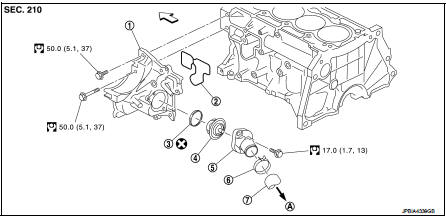

Exploded View

1. Thermostat housing

2. Gasket

3. Rubber ring

4. Thermostat

5. Water inlet

6. Clamp

7. Radiator hose (upper)

A. To radiator

Engine front

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-11, "Draining".

CAUTION:

Perform this step when engine is cold.

2. Remove intake manifold. Refer to EM-28, "Exploded View".

3. Disconnect radiator hose (lower) (RH) from water inlet. Refer to CO-17, "Exploded View".

4. Remove water inlet and thermostat.

• Engine coolant leakage from cylinder block, so have a receptacle ready below.

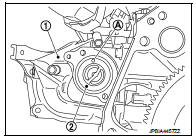

Thermostat housing

1. Drain engine coolant. Refer to CO-11, "Draining".

2. Remove alterator. Refer to CHG-30, "MR16DDT : Exploded View".

3. Remove water pump. Refer to CO-22, "Exploded View".

4. Disconnect water hose, and them remove thermostat housing.

INSTALLATION

Note the following, and install in the reverse order of removal.

Thermostat

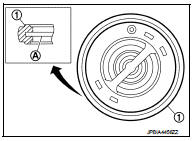

• Install thermostat with making rubber ring (1) groove fit to thermostat flange (A) with the whole circumference.

• Install thermostat (2) with jiggle valve (A) facing upwards.

1 : Thermostat housing

Thermostat housing

• Install in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

Thermostat

• Place a thread (A) so that it is caught in the valves of thermostat

(1). Immerse fully in a container (B) filled with water. Heat while

stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the full open valve lift amount.

• After checking the maximum valve lift amount, lower the water temperature and check the valve closing temperature.

Standard: Refer to CO-29, "Thermostat".

• If out of the standard, replace thermostat.

INSPECTION AFTER INSTALLATION

• Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the radiator cap tester (commercial service tool). Refer to CO-11, "Inspection".

• Start and warm up the engine. Check visually that there is no leakage of engine coolant.

Water pump

Water pump

Exploded View

1. Gasket

2. Water pump

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-11, ...

Water outlet

Water outlet

Exploded View

1. Heater pipe bracket

2. Radiator cap

3. Water outlet adaptor

4. Clamp

5. Water outlet hose

6. Clamp

7. Heater hose

8. Clamp

9. Water outlet

10. Clamp

11. Heater hos ...

Other materials:

P0132 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal is not inordinately high.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

...

Installing top tether strap

WARNING

Child restraint anchorages are designed to withstand only those loads imposed

by correctly fitted child restraints.

Under no circumstances are they to be used to attach adult seat belts, or other

items or equipment to the vehicle. Doing so could damage the child restraint anchorages. ...

B2557 vehicle speed

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2557 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2557 is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...