Nissan Juke Service and Repair Manual : Water pump

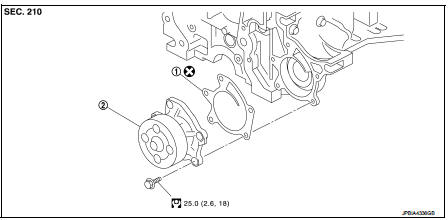

Exploded View

1. Gasket

2. Water pump

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-11, "Draining".

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belt.

2. Steer front wheel to the right.

3. Remove front fender protector (RH). Refer to EXT-22, "Exploded View".

4. Remove drive belt. Refer to EM-155, "Removal and Installation".

5. Remove water pump.

• Engine coolant will leak from cylinder block, so have a receptacle ready below.

CAUTION:

• Handle water pump vane so that it does not contact any other parts.

• Water pump cannot be disassembled and should be replaced as a unit.

INSTALLATION

Install in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

• Check visually that there is no significant dirt or rusting on water pump body and vane (A).

• Check that there is no looseness in vane shaft, and that it turns smoothly when rotated by hand.

• Replace water pump, if necessary.

INSPECTION AFTER INSTALLATION

• Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the radiator cap tester (commercial service tool). Refer to CO-11, "Inspection".

• Start and warm up the engine. Check visually that there is no leakage of engine coolant.

Cooling fan

Cooling fan

Exploded View

1. Fan motor

2. Fan shroud

3. Cooling fan

A. Apply on fan motor shaft

: N·m (kg-m, in-lb)

: Apply genuine high strength thread

locking sealant or equivalent.

Removal and Ins ...

Thermostat

Thermostat

Exploded View

1. Thermostat housing

2. Gasket

3. Rubber ring

4. Thermostat

5. Water inlet

6. Clamp

7. Radiator hose (upper)

A. To radiator

Engine front

: N·m (kg-m, ft-lb)

: Always ...

Other materials:

ECU diagnosis information

ECM

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

NOTE:

• ECM is located in the engine room left side near battery.

• When disconnecting ECM harness connector (1), loosen (B) it with

levers as far as they will go as shown in the figure.

2 : ECM

A : Fasten

• Pulse signal is measured by ...

C1105, C1106, C1107, C1108 wheel sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-I ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...