Nissan Juke Service and Repair Manual : Water outlet

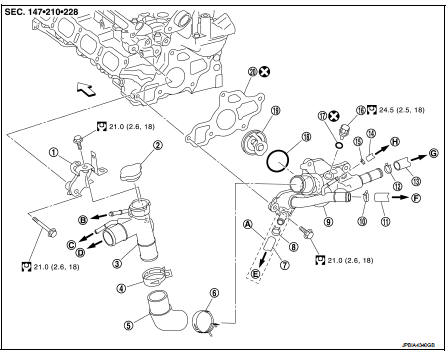

Exploded View

1. Heater pipe bracket

2. Radiator cap

3. Water outlet adaptor

4. Clamp

5. Water outlet hose

6. Clamp

7. Heater hose

8. Clamp

9. Water outlet

10. Clamp

11. Heater hose

12. Heater hose

13. Clamp

14. Heater hose

15. Clamp

16. Engine coolant temperature sensor

17. Gasket

18. Rubber ring

19. Water control value

20. Gasket

Engine front

Engine front

A. For CVT models

B. To reservoir tank

C. To heater hose

D. To radiator hose (upper)

E. To CVT oil warmar

F. To heater hose

G. To heate hose

H. To turbocharger inlet tube

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-11, "Draining".

CAUTION:

• Perform this step when engine is cold.

2. Remove engine cover. Refer to EM-25, "Exploded View".

3. Remove battery. PG-124, "Exploded View".

4. Remove air duct (duct side) and air cleaner cover assembly and air cleaner body assembly.

5. Disconnect radiator hose (upper). Refer to CO-17, "Exploded View".

6. Remove water outlet adaptor.

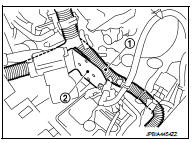

7. Disconnect connectors of engine harness around the battery.

8. Remove bracket (2), and disconnect engine harness clip.(transmission side and water outlet side) 9. Disconnect crankshaft position sensor harness connector.

10. Move engine (1) harness, and keep a service area.

11. Remove water hose and heater hose.

12. Remove water outlet.

13. Remove engine coolant temperature sensor from water outlet, if necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

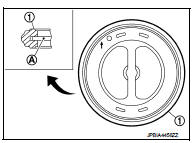

Water Control valve

• Install water control valve with making rubber ring (1) groove fit to

water control valve flange (A) with the whole circumference.

• Install water control valve (2) with the arrow (A) facing up and the frame center part (B) facing upwards.

1 : Water control valve

Inspection

INSPECTION AFTER REMOVAL

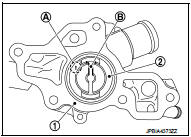

Water Control Valve

• Place a thread (A) so that it is caught in the valves of water control valve (1). Immerse fully in a container (B) filled with water. Heat while stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the continuous valve lifting toward maximum valve lift.

NOTE

:

The maximum valve lift amount standard temperature for water

control valve is the reference value.

• After checking the maximum valve lift amount, lower the water temperature and check the valve closing temperature.

Standard: Refer to CO-29, "Water Control Valve".

• If out of the standard, replace water control valve.

INSPECTION AFTER INSTALLATION

• Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the radiator cap tester (commercial service tool). Refer to CO-11, "Inspection".

• Start and warm up the engine. Check visually that there is no leakage of engine coolant.

Thermostat

Thermostat

Exploded View

1. Thermostat housing

2. Gasket

3. Rubber ring

4. Thermostat

5. Water inlet

6. Clamp

7. Radiator hose (upper)

A. To radiator

Engine front

: N·m (kg-m, ft-lb)

: Always ...

Other materials:

Power supply and ground circuit

Diagnosis Procedure

1.CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected

circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK ...

Exterior and interior lights

: See a NISSAN dealer for replacement.

NOTE: Always check with the Parts Department at a NISSAN dealer for the latest

information about parts.

: REMOVE

: INSTALL

Replacement procedures

All other lights are either type A, B, C, D or E.

When replacing a bulb, first remove the lens and/or c ...

B2195 anti-scanning

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected?

YES >> Refer to SEC-62, "Diagnosis Procedure".

NO >> ...