Nissan Juke Service and Repair Manual : Removal and Installation

REMOVAL

1. Remove rear propeller shaft assembly. Refer to DLN-121, "Removal and Installation".

2. Remove rear drive shaft. Refer to RAX-17, "Removal and Installation".

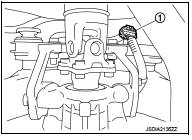

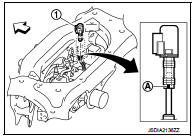

3. Disconnect sub-harness connector (1).

4. Remove rear final drive breather hose.

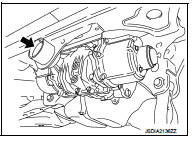

5. Support rear final drive assembly with a suitable jack.

6. Remove rear final drive mounting bolt (

) at rear suspension

member.

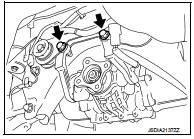

7. Remove final drive mounting bolts and nuts (

), and then

remove rear final drive assembly from final drive mounting

bracket.

CAUTION:

Secure final drive assembly to a suitable jack while removing

it.

8. Remove fuel tank. Refer to FL-23, "4WD : Removal and Installation".

9. Remove final drive mounting bracket.

INSTALLATION

Note the following, and install in the reverse order of removal.

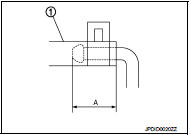

• Install the breather hose (1) to breather tube until dimension (A) shown as follows.

A:

Final drive side : 20mm (0.79 in)

Breather side : 20mm (0.79 in)

CAUTION:

• Never reuse hose clamps.

• Install the hose clamps, with the tab facing vehicle rear.

• If remove breather hose, install breather hose (1) as shown in the figure.

Vehicle front

- Install breather hose with paint mark (A) facing vehicle rear.

• When oil leaks while removing final drive assembly, check oil level after the installation. Refer to DLN-132, "Inspection".

• When replacing rear final drive assembly, perform writing unit parameter. Refer to DLN-39, "Work Procedure".

Exploded View

Exploded View

1. Final drive mounting bracket

2. Washer

3. Rear final drive assembly

: Vehicle front

: N·m (kg-m, ft-lb)

: Never reuse parts

: Apply multi purpose grease

: Apply gear oil.

...

Other materials:

P0300, P0301, P0302, P0303, P0304 misfire

DTC Logic

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, ECM can determine that a misfire is

occurring.

The misfire detection logic consists of the following t ...

B210F shift position/clutch interlock switch

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B210F is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to PCS-

30, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Shift selector lever to the P position.

2. Turn ign ...

P1220 fuel pump control module (FPCM)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

• Before performing the following procedure, confi ...