Nissan Juke Service and Repair Manual : Periodic maintenance

GEAR OIL

Inspection

OIL LEAKAGE

Make sure that gear oil is not leaking from transaxle or around it.

OIL LEVEL

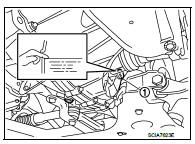

1. Remove filler plug (1) and gasket from transaxle case.

2. Check the oil level from filler plug mounting hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

3. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

4. Tighten filler plug to the specified torque. Refer to TM-88, "Exploded View".

Draining

1. Start engine and let it run to warm up transaxle.

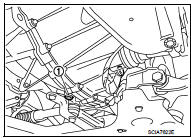

2. Stop engine. Remove drain plug (1) and gasket, using a socket [Commercial service tool] and then drain gear oil.

3. Set a gasket on drain plug and install it to clutch housing, using a socket [Commercial service tool].

CAUTION:

Never reuse gasket.

4. Tighten drain plug to the specified torque. Refer to TM-88, "Exploded View".

Refilling

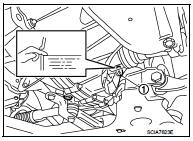

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until oil level reaches the specified limit at filler plug mounting hole as shown in the figure.

Oil grade and viscosity : Refer to MA-13, "Fluids and Lubricants".

Oil capacity : Refer to TM-123, "General Specifications".

3. After refilling gear oil, check the oil level. Refer to TM-75, "Inspection".

4. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

5. Tighten filler plug to the specified torque. Refer to TM-88, "Exploded View".

Symptom diagnosis

Symptom diagnosis

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

Use the chart below to find the cause of the symptom. The numbers indicate

the order of the inspection. If necessary, ...

Other materials:

Power supply and ground circuit

Diagnosis Procedure

1.CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected

circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK ...

Towing your vehicle

When towing your vehicle, all State (Provincial in Canada) and local regulations

for towing must be followed. Incorrect towing equipment could damage your vehicle.

Towing instructions are available from a NISSAN dealer. Local service operators

are familiar with the applicable laws and procedur ...

P0225 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

Х If DTC P0225 is displayed with DTC P0641, first perform trouble diagnosis for

DTC P0641. Refer to

EC-974, "DTC Logic".

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Grou ...