Nissan Juke Service and Repair Manual : Rear window defogger

Description

Heats the heating wire with the power supply from the rear window defogger relay to prevent the rear window from fogging up.

Component Function Check

1.CHECK FUNCTION

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the rear window heating wire is getting warmer.

Is the inspection result normal? YES >> Rear window defogger is OK.

NO >> Refer to DEF-30, "Diagnosis Procedure"

Diagnosis Procedure

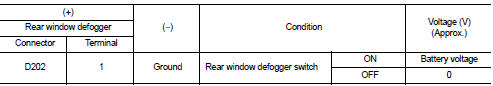

1.CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger connector.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

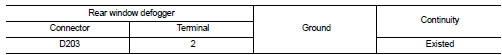

2.CHECK REAR WINDOW DEFOGGER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear window defogger harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK FILAMENT

Refer to DEF-46, "Inspection and Repair".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair filament.

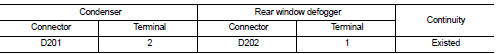

4.CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT 1

1. Turn ignition switch OFF.

2. Disconnect condenser connector.

3. Check continuity between condenser harness connector and rear window defogger harness connector.

4. Check continuity between condenser connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness.

5.CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT 2

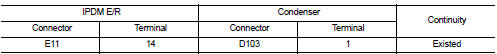

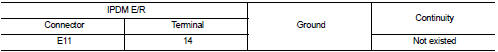

1. Disconnect IPDM E/R connectors.

2. Check continuity between IPDM E/R harness connector and condenser harness connector.

3. Check continuity between IPDM E/R connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.CHECK CONDENSER

Refer to DEF-32, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace condenser. Refer to DEF-48, "Removal and Installation".

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident" Is the inspection result normal? YES >> INSPECTION END

NO >> Repair or replace harness or connector.

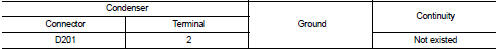

Component Inspection

1.CHECK CONDENSER

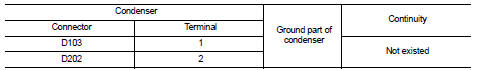

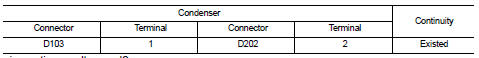

1. Turn ignition switch OFF.

2. Disconnect condenser connector.

3. Check continuity between condenser connector and ground part of condenser.

4. Check continuity between condenser terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace condenser. Refer to DEF-48, "Removal and Installation".

Rear window defogger relay

Rear window defogger relay

Description

The rear window defogger is operated by turning the rear window defogger

switch ON.

Component Function Check

1.CHECK FUNCTION

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using ...

Door mirror defogger

Door mirror defogger

Description

Heats the heating wire with the power supply from the rear window defogger

relay to prevent the door mirror

from fogging up.

Component Function Check

1.CHECK DOOR MIRROR DEFOGGER

1. ...

Other materials:

Parking brake control

Exploded View

2WD

1. Parking brake lever assembly

2. Adjusting nut

3. Parking brake switch

4. Front cable

5. Rear cable (LH)

6. Rear cable (RH)

: Apply multi-purpose grease.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every

disassembly.

4WD

1. Parking brake ...

P2A00 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the A/F signal computed by ECM from the A/F sensor

1 signal is monitored so it will

not shift to LEAN side or RICH side.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always ...

G sensor

Exploded View

1. Bracket

2. G sensor

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

Removal and Installation

CAUTION:

• Never drop or strike G sensor, because it has little tolerance for impact.

• Never use a power tool to avoid impact.

REMOVAL

1. Disconnect the battery cable ...