Nissan Juke Service and Repair Manual : Rear oil seal

REAR OIL SEAL : Removal and Installation

REMOVAL

1. Remove transaxle assembly. Refer to TM-301, "Exploded View" (CVT models) or TM-84, "MR16DDT : Exploded View" (M/T models).

2. Remove clutch cover and clutch disk (M/T models). Refer to CL-29, "EXCEPT FOR K9K : Exploded View".

3. Remove drive plate (CVT models) or flywheel (M/T models). Refer to EM-103, "Exploded View".

4. Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

1. Apply the liquid gasket lightly to entire outside area of new rear oil seal.

Use Genuine Liquid Gasket or equivalent.

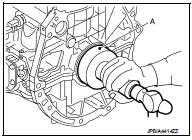

2. Install rear oil seal so that each seal lip is oriented as shown in the figure.

A : Dust seal lip

B : Oil seal lip

: Engine outside

: Engine outside

: Engine inside

: Engine inside

• Press-fit rear oil seal with a suitable drift (A) outer diameter 115 mm (4.53 in) and inner diameter 90 mm (3.54 in).

CAUTION:

• Be careful not to damage crankshaft and cylinder block.

• Press-fit oil seal straight to avoid causing burrs or tilting.

• Never touch grease applied onto oil seal lip.

• Press in rear oil seal (1) to the position as shown in the figure.

A : Rear end surface of cylinder block

3. Install in the reverse order of removal, for the rest of parts.

Front oil seal

Front oil seal

FRONT OIL SEAL : Removal and Installation

REMOVAL

1. Remove the following parts.

• Front fender protector (RH): Refer to EXT-22, "Exploded View".

• Drive belt: Refer to EM-20, "Expl ...

Cylinder head

Cylinder head

Exploded View

REMOVAL

1. Cylinder head assembly

2. Cylinder head bolt

3. Cylinder head gasket

A. Tightening must be done following

the installation procedure.

Refer to EM-91

: N·m (kg-m, ...

Other materials:

Back-up lamp switch : Component Inspection

1.CHECK BACK-UP LAMP SWITCH

1. Disconnect position switch connector. Refer to TM-77, "Removal and

Installation".

2. Check continuity between position switch terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace position switch. Refer to TM-7 ...

P0504 ASCD brake SWI

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO ...

Shift position indicator circuit

Description

• TCM sends position indicator signals to combination meter by CAN

communication line.

• Manual mode switch position is indicated on shift position indicator

Component Function Check

1.CHECK SHIFT POSITION INDICATOR

CAUTION:

Always drive vehicle at a safe speed.

1. Start engine. ...