Nissan Juke Service and Repair Manual : P2118 throttle control motor

DTC Logic

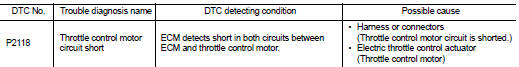

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 2 seconds.

2. Start engine and let it idle for 5 seconds.

3. Check DTC.

Is DTC detected? YES >> Go to EC-744, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

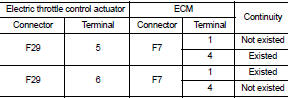

2.CHECK THROTTLE CONTROL MOTOR OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect electric throttle control actuator harness connector.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

3.CHECK THROTTLE CONTROL MOTOR

Refer to EC-745, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 5.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness or connectors.

5.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

Replace electric throttle control actuator. Refer to EM-163, "Exploded View".

>> INSPECTION END

Component Inspection

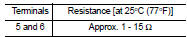

1.CHECK THROTTLE CONTROL MOTOR

1. Disconnect electric throttle control actuator harness connector.

2. Check resistance between electric throttle control actuator terminals as follows.

YES >> INSPECTION END

NO >> GO TO 2.

2.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

Replace electric throttle control actuator. Refer to EM-163, "Exploded View".

>> INSPECTION END

P2101 electric throttle control function

P2101 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P2101 is displayed with DTC P2100, first perform the trouble diagnosis

for DTC P2100. Refer

to EC-737, "DTC Logic".

• If DTC P2101 is disp ...

P2119 electric throttle control actuator

P2119 electric throttle control actuator

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 se ...

Other materials:

Blower fan on signal

Component Function Check

1.CHECK BLOWER FAN ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “FAN ON SIG” in “DATA MONITOR” mode.

4. Check blower fan ON signal when the fan control dial is operated.

Is the inspection re ...

Air conditioning system refrigerant and lubricant recommendations

The air conditioning system in your NISSAN vehicle must be charged with the

refrigerant HFC-134a (R-134a) and the oil, NISSAN A/C system oil Type R or the exact

equivalents.

CAUTION

The use of any other refrigerant or oil will cause severe damage to the air

conditioning system and will requi ...

P0697 sensor power supply

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF and wait at least 4 minutes.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2 ...