Nissan Juke Service and Repair Manual : P1614 chain of IMMU-KEY

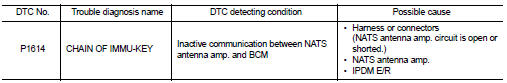

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE 1

1. Contact Intelligent Key backside to push-button ignition switch.

2. Check DTC in “Self Diagnostic Result” mode of “ENGINE” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-55, "Diagnosis Procedure".

NO >> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE 2

1. Press the push-button ignition switch.

2. Check DTC in “Self Diagnostic Result” mode of “ENGINE” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-55, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

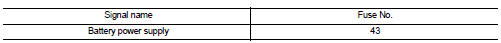

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check that the following fuse in IPDM E/R is not blown.

Is the fuse fusing? YES >> Replace the blown fuse after repairing the cause of blowing.

NO >> GO TO 2.

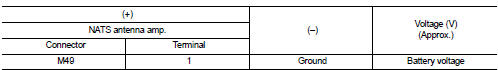

2.CHECK NATS ANTENNA AMP. POWER SUPPLY

1. Disconnect NATS antenna amp. connector.

2. Check voltage between NATS antenna amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

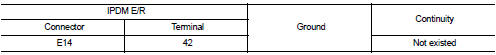

3.CHECK NATS ANTENNA AMP. POWER SUPPLY CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and NATS antenna amp. connector

3. Check continuity between IPDM E/R harness connector and ground.

the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation".

NO >> Repair or replace harness.

4.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL 1

1. Connect NATS antenna amp. connector.

2. Disconnect BCM connector.

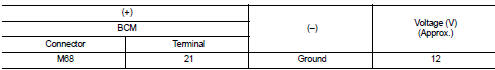

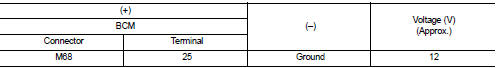

3. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL CIRCUIT 1

1. Disconnect NATS antenna amp. connector.

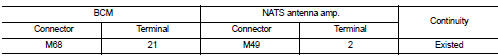

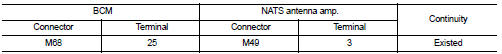

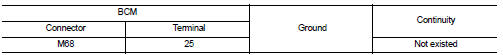

2. Check continuity between BCM harness connector and NATS antenna amp. connector.

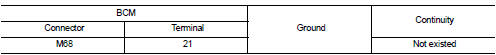

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

NO >> Repair or replace harness.

6.CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL 1

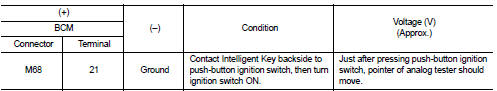

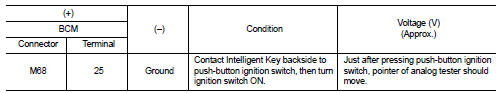

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground using analog tester.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

7.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL 2

1. Disconnect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 8.

8.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL CIRCUIT 2

1. Disconnect NATS antenna amp. connector.

2. Check continuity between BCM harness connector and NATS antenna amp. connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

NO >> Repair or replace harness.

9.CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL 2

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground using analog tester.

Is the inspection result normal? YES >> GO TO 10.

NO >> Replace NATS antenna amp. Refer to SEC-167, "Removal and Installation".

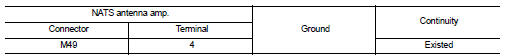

10.CHECK NATS ANTENNA AMP. GROUND CIRCUIT

1. Disconnect NATS antenna amp. connector.

2. Check continuity between NATS antenna amp. harness connector and ground.

Is the inspection result normal?

YES >> GO TO 11.

NO >> Repair or replace harness.

11.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

P1612 chain of ECM-IMMU

P1612 chain of ECM-IMMU

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P1612 is displayed with DTC U1000 (for BCM), first perform the trouble

diagnosis for DTC U1000.

Refer to BCS-83, "DTC Logic".

• If DTC ...

P1616 ECM

P1616 ECM

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION

1. Turn ignition switch ON amd wait 2 seconds or more.

2. Check DTC in “Self Diagno ...

Other materials:

Engine does not start or starts with difficulty

Description

CHART 2: ENGINE DOES NOT START OR STARTS WITH DIFFICULTY

Diagnosis Procedure

1.CHECK FUEL

Check that the fuel reservoir is correctly filled and with the right fuel.

>> GO TO 2.

2.CHECK BATTERY

Check the battery. Refer to PG-124, "Removal and Installation".

I ...

Cylinder Block

AVAILABLE PISTON

PISTON RING

PISTON PIN

CONNECTING ROD

*: After installing in connecting rod

CRANKSHAFT

*: Total indicator reading ...

P0340 CMP sensor (PHASE)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...