Nissan Juke Service and Repair Manual : P1554 battery current sensor

DTC Logic

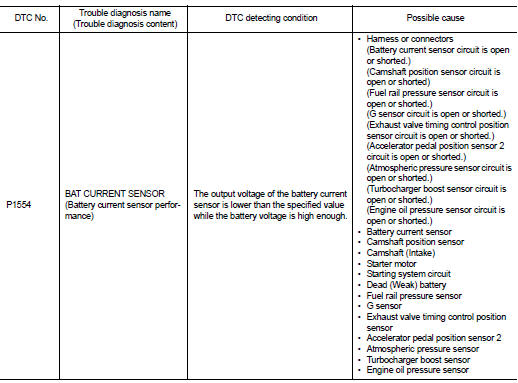

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-337, "Component Function Check".

NOTE

:

Use component function check to check the overall function of the battery

current sensor circuit. During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-338, "Diagnosis Procedure".

Component Function Check

1.PRECONDITIONING

TESTING CONDITION: • Before performing the following procedure, confirm that battery voltage is more than 12.8 V at idle.

• Before performing the following procedure, confirm that all load switches and A/C switch are turned OFF.

>> GO TO 2.

2.PERFORM COMPONENT FUNCTION CHECK

With CONSULT-III

With CONSULT-III

1. Start engine and let it idle.

2. Select “BAT CUR SEN” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Check “BAT CUR SEN” indication for 10 seconds.

“BAT CUR SEN” should be above 2,300 mV at least once.

Without CONSULT-III

Without CONSULT-III

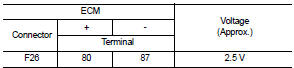

1. Start engine and let it idle.

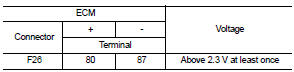

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-338, "Diagnosis Procedure".

Diagnosis Procedure

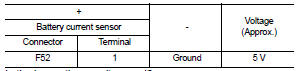

1.CHECK BATTERY CURRENT SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect battery current sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between battery current sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

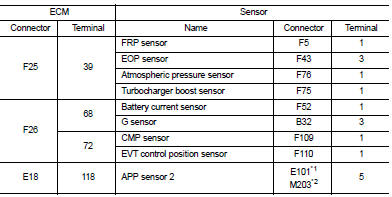

2.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals.

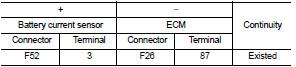

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between battery current sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT

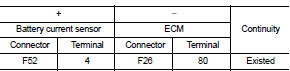

1. Check the continuity between battery current sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts

5.CHECK BATTERY CURRENT SENSOR

Check the battery current sensor. Refer to EC-330, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace battery negative cable assembly. Refer to PG-125, "Exploded View".

Component Inspection

1.CHECK BATTERY CURRENT SENSOR

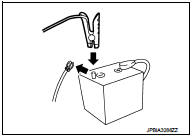

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector and ground.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-111, "How to Handle Battery".

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace battery negative cable assembly. Refer to PG-125, "Exploded View".

P1553 battery current sensor

P1553 battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following before conducting

the next ...

P1556, P1557 battery temperature

sensor

P1556, P1557 battery temperature

sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at lest 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and ...

Other materials:

Rear door lock

Exploded View

1. Outside handle assembly

2. Rear door sealing screen

3. Door lock assembly

4. TORX bolt

5. Inside handle

: Clip

: Pawl

: Vehicle front

: Do not reuse

: N·m (kg-m, in-lb)

: Body grease

Door lock

DOOR LOCK : Removal and Installation

REMOVAL

1. Remove rear door glass ...

P0611 ECM protection

Description

This DTC is detected when the ECM protective function is activated due to an

extreme temperature increase

in ECM, resulting from severe conditions such as heavy load driving.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

This DTC ...

C1604 torque sensor

DTC Logic

DTC DETECTION LOGI

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With C ...